Environmentally Friendly High Efficiency Filling Machine for Curing Agent in Pail With Capping

Environmentally Friendly High-Efficiency Filling Machine for Curing Agent in Pail with Capping

Overview:

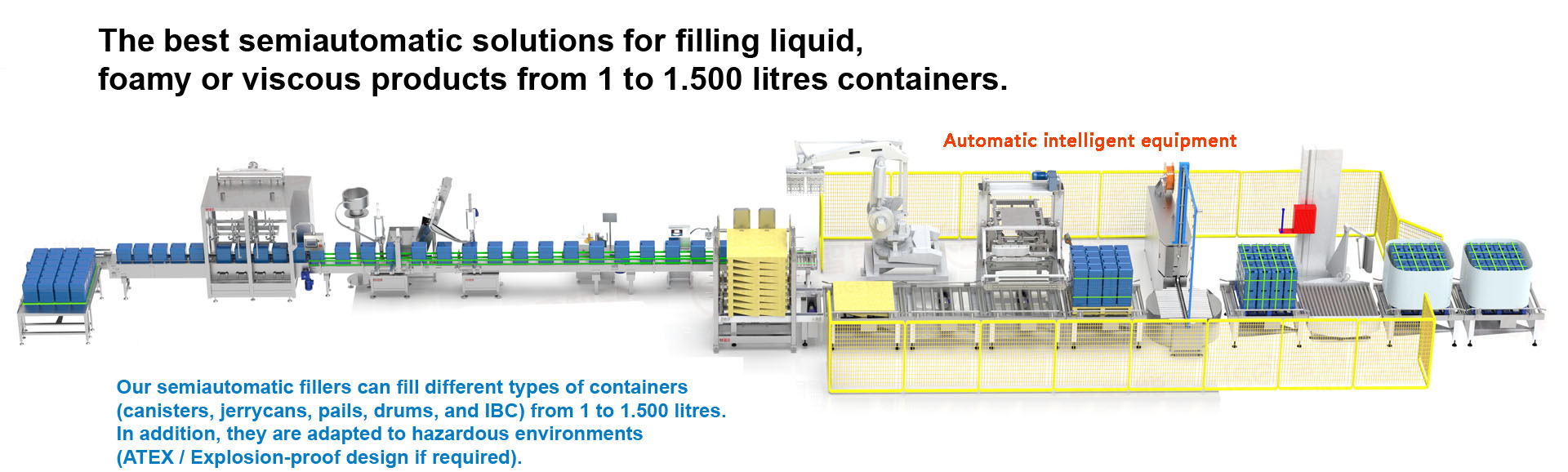

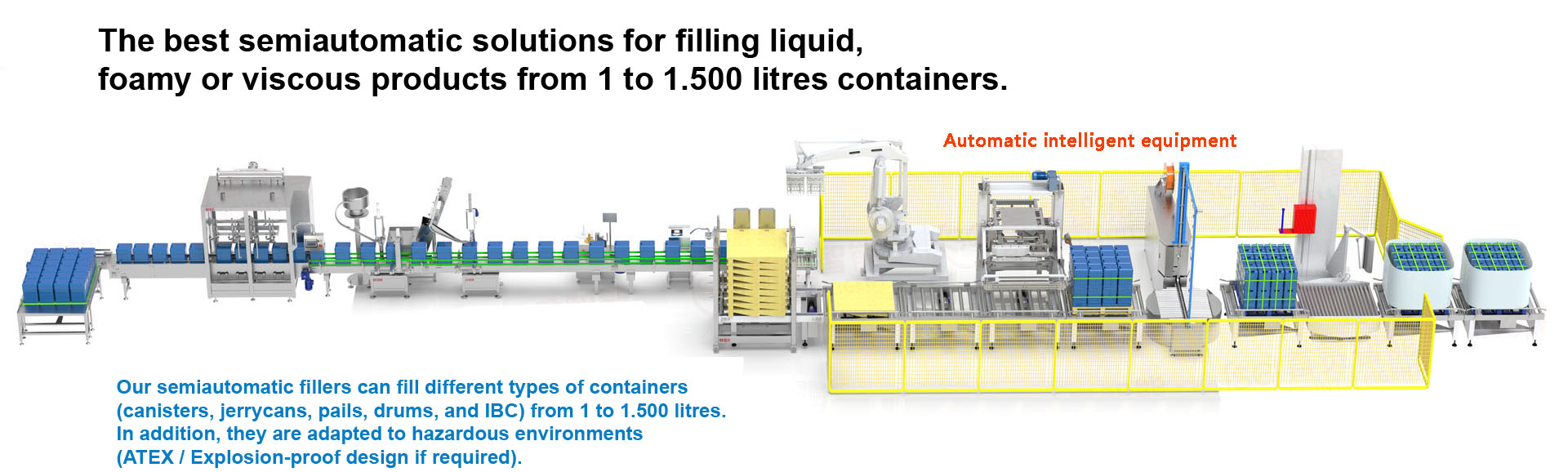

The high-efficiency, environmentally friendly filling machine is designed for safe, precise, and automated filling of curing agents into pails, followed by automatic capping. This system prioritizes minimizing waste, reducing emissions, and ensuring worker safety while maximizing productivity. It is ideal for industries handling hazardous or viscous liquids like curing agents, resins, and chemicals.

Key Features:

High-Efficiency Filling:

Automatic Filling: Programmable volume control ensures ±0.5% accuracy for consistent fill levels.

Viscous Liquid Handling: Positive displacement pumps or peristaltic pumps handle high-viscosity curing agents (up to 5000 cP).

Flow Control Valves: Adjustable speed prevents splashing, foaming, or air entrapment.

Environmentally Friendly Design:

Drip-Free Nozzles: Anti-drip technology and vacuum breakers minimize product loss and spills.

Nitrogen Blanketing (Optional): Inert gas purging reduces VOC emissions and oxidation during filling.

Low-Emission Operation: Enclosed filling area with fume extraction (optional) to capture vapors.

Automated Capping:

Integrated Capping System: Automatically seals pails with tamper-evident or induction caps after filling.

Torque Control: Adjustable tightening to ensure secure closure without over-tightening.

Compatibility: Suitable for plastic, metal, or composite caps.

Safety & Compliance:

ATEX/IECEx Certification: Explosion-proof design for hazardous environments (Zone 1/21 or Zone 2/22).

Stainless Steel Construction (304/316): Corrosion-resistant materials for chemical compatibility.

Static Grounding: Prevents static buildup during filling and capping.

Precision Metering:

Weigh-Based or Volumetric Filling: Options for gravity or weight-based measurement.

Pre-Set Batch Recipes: Quick adjustment for different product volumes or container sizes.

Curing Agent Compatibility:

PTFE/FKM Seals: Resistant to aggressive chemicals and high viscosity.

Heated Jackets (Optional): Prevents crystallization or clogging for temperature-sensitive curing agents.

User-Friendly Operation:

Touchscreen HMI: Intuitive interface for setting parameters, monitoring production, and troubleshooting.

Foot Pedal or Button Control: Hands-free operation for safety and efficiency.

Remote Access (Optional): Ethernet or Wi-Fi connectivity for data logging and remote diagnostics.

Maintenance & Cleanliness:

Tool-Free Nozzle Removal: Simplifies cleaning and maintenance.

Self-Purging Function: Automatically cleans the nozzle after each cycle.

Inline Filters: Prevents contamination and clogging.

Customization Options:

Multi-Lane Configuration: Add additional filling heads for higher throughput.

Labeling Integration (Optional): Apply barcodes, batch numbers, or expiration dates.

Pail Conveyor System (Optional): Automates container loading and unloading.

Compliance & Certifications:

CE Marking: Complies with EU safety and environmental standards.

ISO 9001 & 14001 Certified: Adherence to quality and environmental management systems.

GMP Compatible (Optional): For pharmaceutical or food-grade applications.

Applications:

Curing Agents: Filling and capping epoxy, polyurethane, or other reactive resin curing agents.

Chemicals & Adhesives: Packaging solvents, adhesives, or corrosive liquids.

Paint & Coatings: Dispensing high-viscosity or hazardous paints into sealed pails.

Pharmaceuticals: Filling and sealing liquid medications or APIs under controlled conditions.

Food & Beverage: Packaging oils, sauces, or syrups in pails (with GMP option).

Operation Steps:

Container Loading: Empty pail is placed on the filling platform (manually or via conveyor).

Nozzle Positioning: Telescopic or fixed nozzle extends into the pail to minimize splashing.

Filling: The machine fills the pail to the preset volume using weight or flow meters.

Capping: Automatic capping system seals the pail with a secure, tamper-evident cap.

Container Removal: Filled and capped pail is manually removed or transferred via conveyor.

Cleanup (Optional): Nozzle self-purges or undergoes manual cleaning.

Benefits:

Efficiency: High-speed filling and automated capping reduce cycle time and labor costs.

Safety: Explosion-proof design, drip-free nozzles, and static grounding ensure hazardous environment compatibility.

Precision: Accurate filling minimizes overfilling, product waste, and material costs.

Environmental Impact: Drip-free operation, nitrogen blanketing, and fume extraction reduce emissions and waste.

Versatility: Suitable for viscous, corrosive, or temperature-sensitive liquids.

Compliance: Meets global safety, environmental, and quality standards (ATEX, CE, ISO).

Low Maintenance: Tool-free cleaning and durable construction minimize downtime.

Why Choose This Machine?

This high-efficiency filling machine with automated capping combines safety, precision, and sustainability into a reliable solution for packaging curing agents and hazardous liquids. With features like ATEX certification, drip-free technology, and automated capping, it ensures compliant, efficient, and environmentally friendly operation in demanding industrial settings.

Immediate Order:

Website: http://m.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com