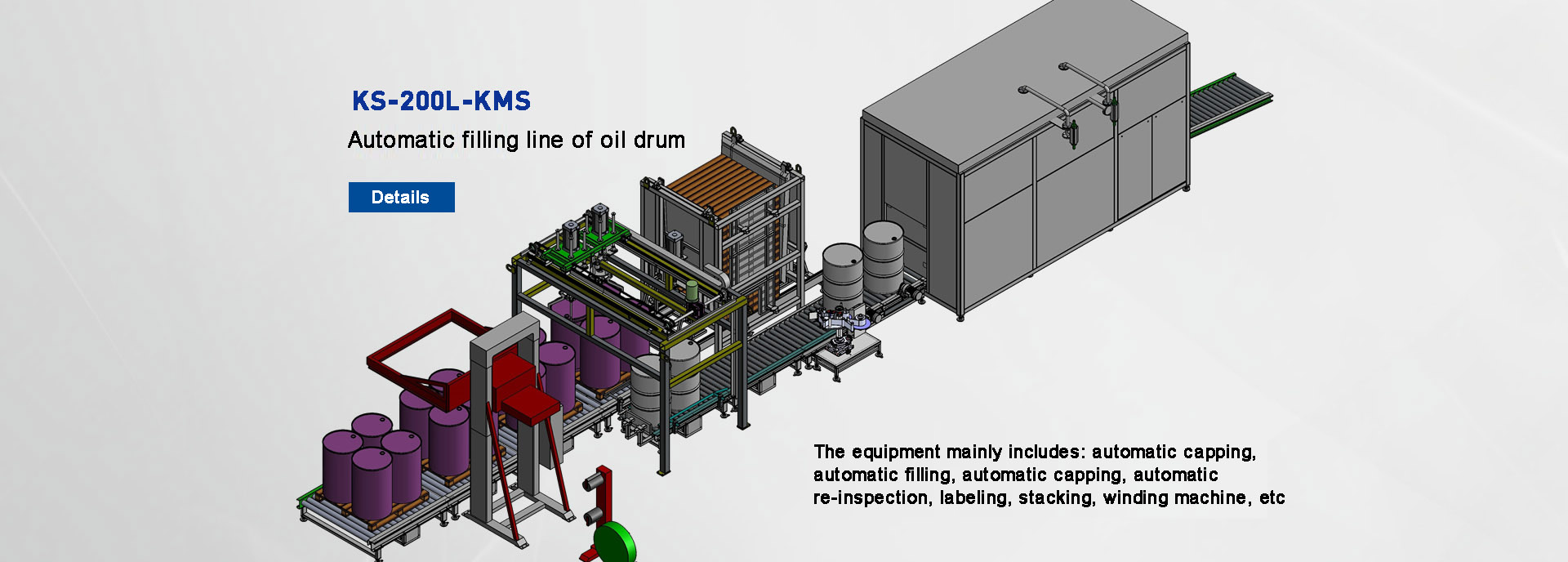

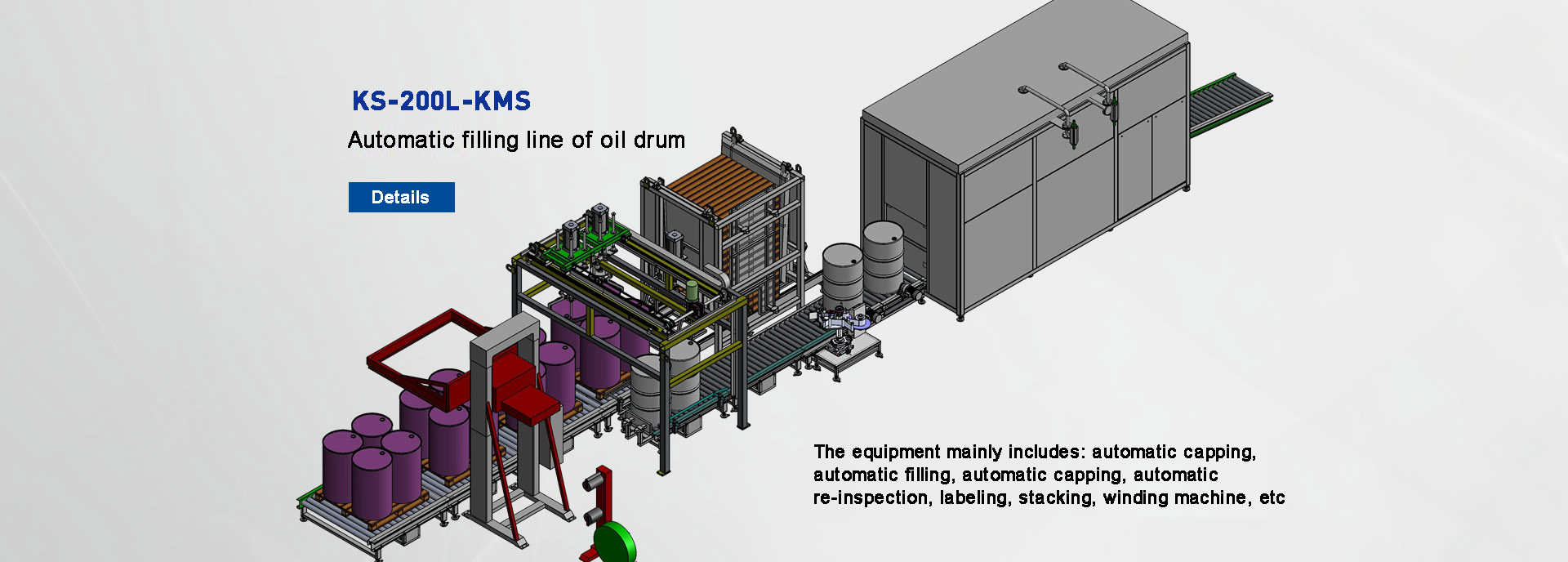

Automatic Double-head Liquid Pail Filling Machine for Engine Oil With a Crown Lid

Automatic Double-Head Liquid Pail Filling Machine for Engine Oil with Crown Lid Sealing

Overview:

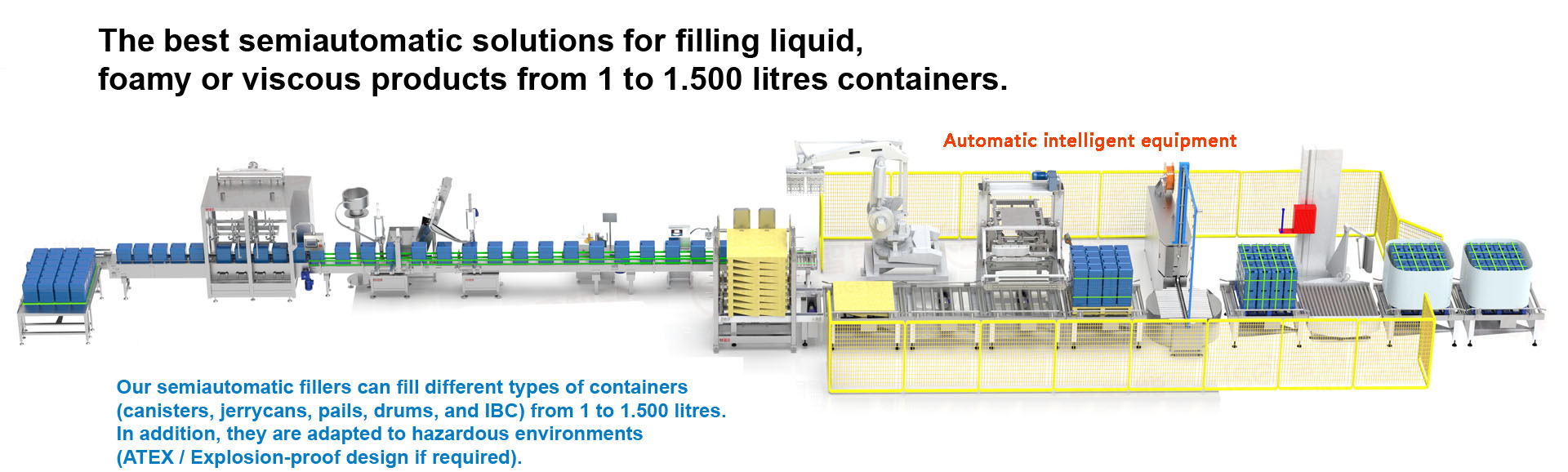

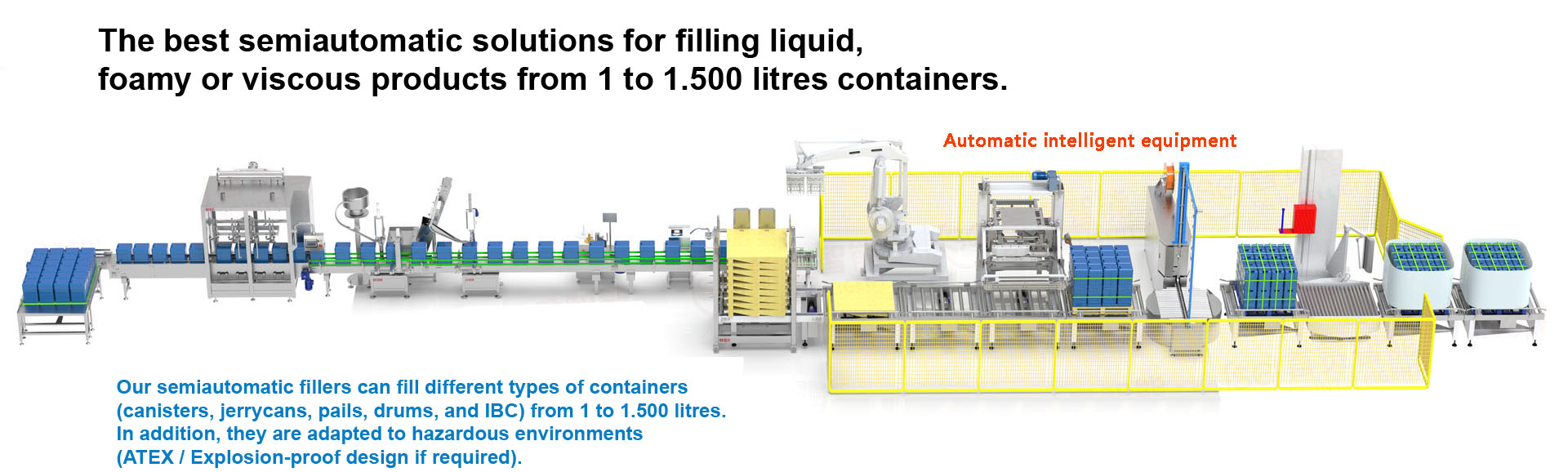

The Automatic Double-Head Liquid Pail Filling Machine is a high-speed, precision-engineered solution designed for efficient filling and sealing of engine oil and other liquids into pails or drums. With its dual-head design, crown lid sealing capability, and advanced automation features, this machine is ideal for engine oil manufacturers, lubricant producers, and industrial packaging operations. It ensures accurate filling, consistent sealing, and enhanced productivity while minimizing operator intervention and product waste.

Key Features:

Dual-Head Filling System:

High Throughput: Two independent filling heads allow simultaneous filling of two pails, doubling production capacity compared to single-head machines.

Precision Filling: Utilizes flow meters or weight-based technology to ensure ±0.5% accuracy in fill volumes.

Adjustable Fill Volumes: Easily configurable for different pail sizes (e.g., 1L, 4L, 20L, 200L) and product viscosities.

Crown Lid Sealing:

Integrated Crimping/Seaming Head: Automatically seals crown lids onto filled pails, ensuring airtight closure and product integrity.

Pneumatic or Servo-Driven Sealing: Reliable and precise lid compression for consistent sealing quality.

Compatible with Standard Crown Lids: Works with industry-standard crown lids (e.g., tinplate or composite).

Engine Oil Compatibility:

Viscous Product Handling: Designed to handle high-viscosity liquids like engine oils, gear oils, and greases.

Heated Hoses (Optional): Prevents product thickening or solidification during filling, especially for cold-weather applications.

Chemical-Resistant Materials: Constructed with stainless steel (304/316L) and corrosion-resistant hoses/seals.

Automation & Efficiency:

Conveyor Integration: Integrates with infeed and outfeed conveyors for seamless workflow.

Touchscreen HMI: User-friendly interface for setting fill volumes, sealing parameters, and monitoring production.

Automated Pail Indexing: Positions pails accurately under the filling heads and sealing station.

Safety & Compliance:

Spill Prevention: Drip trays and nozzle blow-off systems minimize product leakage and contamination.

Emergency Stop & Safety Sensors: Ensures operator safety during operation.

CE/ISO Compliance: Meets international standards for machinery safety and performance.

Customization Options:

Nitrogen Blanketing: Inert gas purging to prevent oxidation or foaming of sensitive products.

Data Logging: Records fill volumes, batch numbers, and timestamps for traceability.

Remote Monitoring: Enables integration with SCADA systems for real-time production tracking.

Durability & Low Maintenance:

Stainless Steel Construction: Robust frame and contact parts resistant to corrosion and wear.

Quick-Change Nozzles: Interchangeable filling nozzles for different pail sizes and product types.

Tool-Free Maintenance: Easy access to components for cleaning, inspection, and replacement.

Applications:

Engine Oil Manufacturers: Filling and sealing engine oils, motor oils, and transmission fluids.

Lubricant Producers: Packaging industrial lubricants, greases, and specialty oils.

Automotive Industry: Bottling or drumming oils for OEM or aftermarket distribution.

Chemical & Industrial Liquids: Filling viscous or non-viscous liquids into pails or drums.

Food & Pharmaceuticals: Sealing pails of edible oils, syrups, or pharmaceutical formulations (with appropriate modifications).

Operation Steps:

Pail Loading: Empty pails are placed on the infeed conveyor.

Automatic Indexing: The machine positions pails under the dual filling heads.

Precision Filling: The filling heads dispense the exact volume of engine oil into each pail.

Crown Lid Sealing: A robotic arm or integrated sealing head places and crimps a crown lid onto the filled pail.

Pail Unloading: Sealed pails are transferred to the outfeed conveyor for labeling or further processing.

Cleanup (Optional): Hose blow-off or automated cleaning systems remove residual product from nozzles.

Benefits:

High Productivity: Dual-head design doubles filling speed vs. single-head machines.

Airtight Seals: Crown lid sealing ensures product freshness and prevents contamination.

Versatility: Handles a wide range of pail sizes and viscous products like engine oil.

Reduced Labor Costs: Minimal operator intervention; automated filling and sealing.

Consistency & Accuracy: Eliminates human error in fill volumes and lid sealing.

Compliance: Meets safety and regulatory standards for industrial packaging.

Low Waste: Drip-free nozzles and precise filling minimize product loss.

Why Choose This Machine?

The Automatic Double-Head Liquid Pail Filling Machine is the ultimate solution for high-speed, precision filling and sealing of engine oil and similar viscous liquids. Its dual-head design, crown lid sealing capability, and robust construction make it perfect for manufacturers seeking efficiency, reliability, and compliance. Whether you’re producing engine oil, lubricants, or industrial fluids, this machine delivers consistent results, reduces labor costs, and ensures product integrity.

Immediate Order:

Website: http://m.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

200L Plastic Bottle Bottle Carbonated Beverage Filling Machine[2025-06-12]

-

Versatile 1-30L Liquid Filling Machine for Efficient Production[2025-07-03]

-

Juice Production Line Juice Washing Filling Numerical Control Automatic[2025-05-06]

-

Semi-Automatic Resin Lubricant Pails Chemical Filling Machine for 20L/30L/40L[2025-05-10]