Industrial Aseptic Bag Filler Machine to Fill Fruit Juice Paste Concentrate in Box Drum Aseptic Bag Filling System

The Industrial Aseptic Bag Filler Machine is a specialized system designed for the hygienic and efficient filling of fruit juice, paste, concentrate, or other liquids into aseptic bags, boxes, drums, or other sterile containers. Below is an overview of its features, applications, and benefits:

Key Features:

Aseptic Filling Technology:

Ensures microbiological safety by filling pre-sterilized containers with ultra-clean liquids in a sterile environment.

Ideal for shelf-stable products that do not require refrigeration after filling.

High-Capacity Filling:

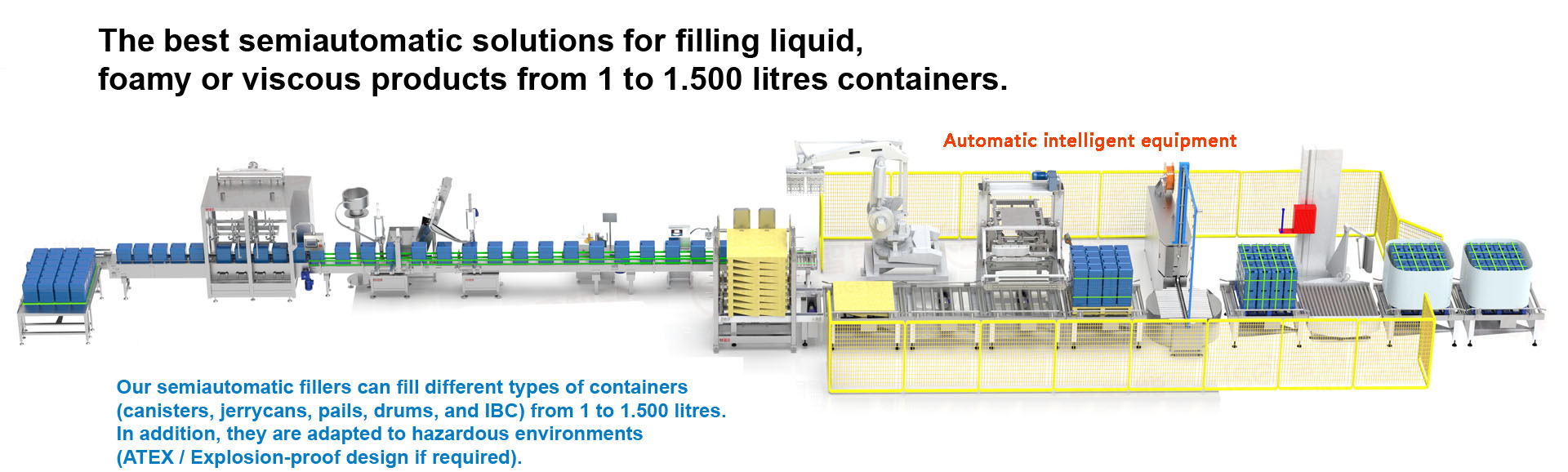

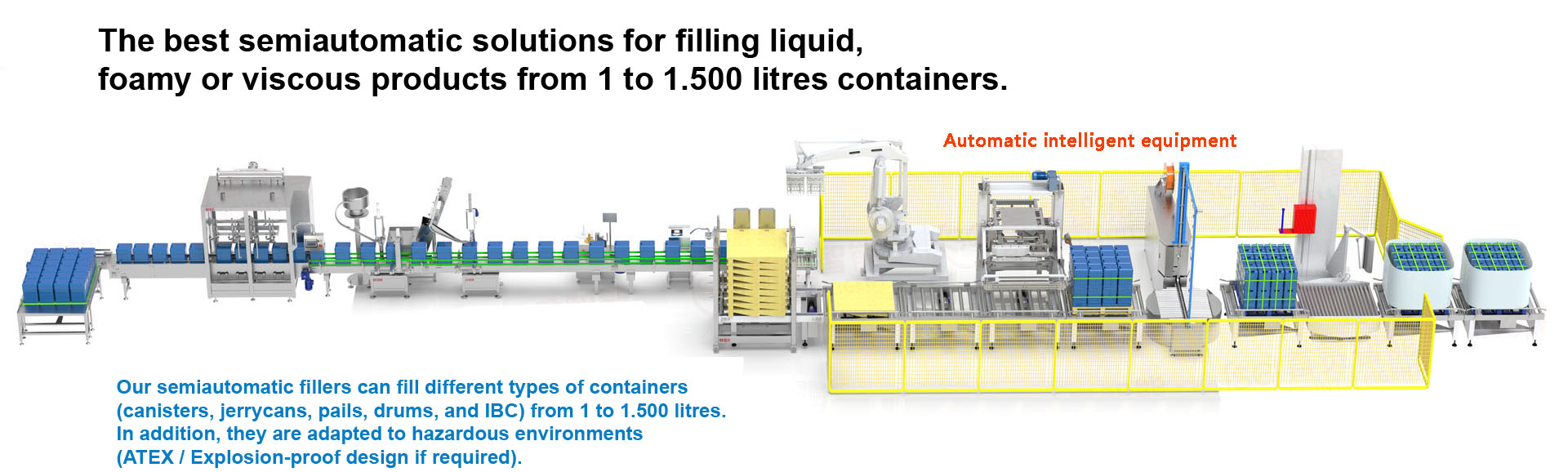

Capable of filling large containers such as aseptic bags, drums, or IBC (Intermediate Bulk Containers) with high precision.

Suitable for both low-viscosity (juices) and high-viscosity (pastes/concentrates) products.

Automated Operation:

Fully automated process from container handling to filling, capping, and sealing.

Reduces labor costs and minimizes human error.

Hygienic Design:

Constructed from stainless steel (304/316L) for corrosion resistance and easy cleaning.

Equipped with CIP (Cleaning in Place) and SIP (Sterilization in Place) systems for thorough sanitation.

FDA and GMP compliant materials ensure food safety.

Precision Metering:

Advanced flow meters or load cells ensure accurate fill volumes, reducing product waste.

Adjustable filling speeds and volumes for flexibility in production.

Temperature Control (Optional):

Heated or cooled filling nozzles to maintain optimal product temperature and prevent clogging.

Insulated piping or jacketed systems for temperature-sensitive products.

Safety and Environmental Protection:

Leak-proof seals, drip trays, and emergency stop buttons prevent spills and contamination.

Energy-efficient design reduces operational costs.

Customizable ODM Design:

Tailored to meet specific requirements, including container sizes, fill volumes, and production speeds.

Options for custom nozzles, capping systems, and labeling solutions.

User-Friendly Interface:

Touchscreen HMI (Human-Machine Interface) for easy setup and operation.

Programmable fill parameters for different products and batches.

Integrated Conveyor System (Optional):

Seamless container handling from pre-sterilized storage to filling and sealing.

Increases throughput and reduces manual labor.

Applications:

Fruit Juice and Beverage Industry: Filling aseptic bags or drums with fruit juice, concentrate, or nectar.

Food Processing: Packaging sauces, pastes, or purees in sterile containers.

Pharmaceuticals: Filling aseptic bags with pharmaceutical liquids or syrups.

Chemical Industry: Packaging chemicals, oils, or solvents in aseptic containers.

Agriculture: Dispensing pesticides, fertilizers, or other agricultural liquids.

Benefits:

Microbiological Safety: Aseptic filling ensures long shelf life without refrigeration or preservatives.

Efficiency: Automated operation increases productivity and reduces labor costs.

Precision: Accurate filling minimizes product waste and ensures consistent quality.

Versatility: Customizable design allows adaptation to various products and container types.

Hygiene: Easy-to-clean components and compliance with food-grade standards ensure product safety.

Scalability: Modular design allows for future expansion or integration into larger production lines.

Why Choose This System?

This Aseptic Bag Filler Machine is ideal for industries requiring hygienic, precise, and efficient filling of liquids into aseptic containers. Its robust construction, advanced safety features, and customization options make it suitable for fruit juice, paste, concentrate, and other liquid products. Whether you’re filling aseptic bags, drums, or boxes, this system provides a reliable solution for maintaining product integrity and extending shelf life.

Important Note:

For food and beverage applications, ensure the system is constructed with FDA and GMP compliant materials. For pharmaceutical or hazardous liquid applications, consult with experts to ensure proper safety protocols and equipment compatibility. Contact GLZON or your equipment supplier for customized solutions and technical assistance.

Immediate Order:

Website: http://m.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com