Automatic Explosion-proof Detergent Coating Multifunctional Liquid Filling Machine_

Automatic Explosion-Proof Detergent/Coating Multifunctional Liquid Filling Machine

Overview

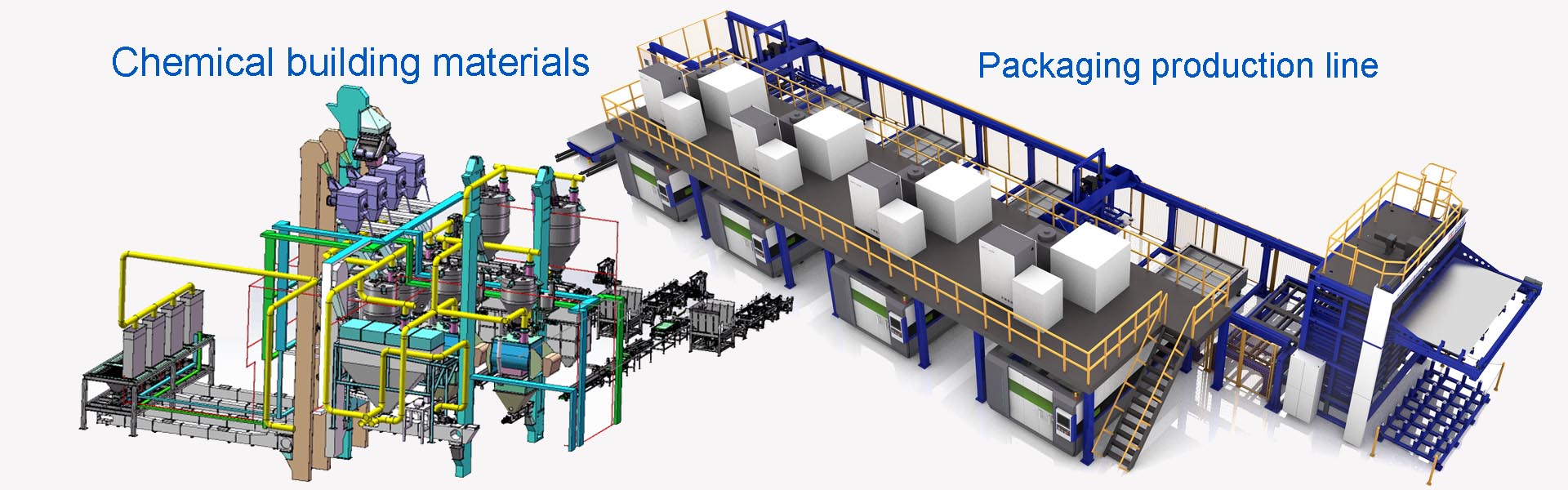

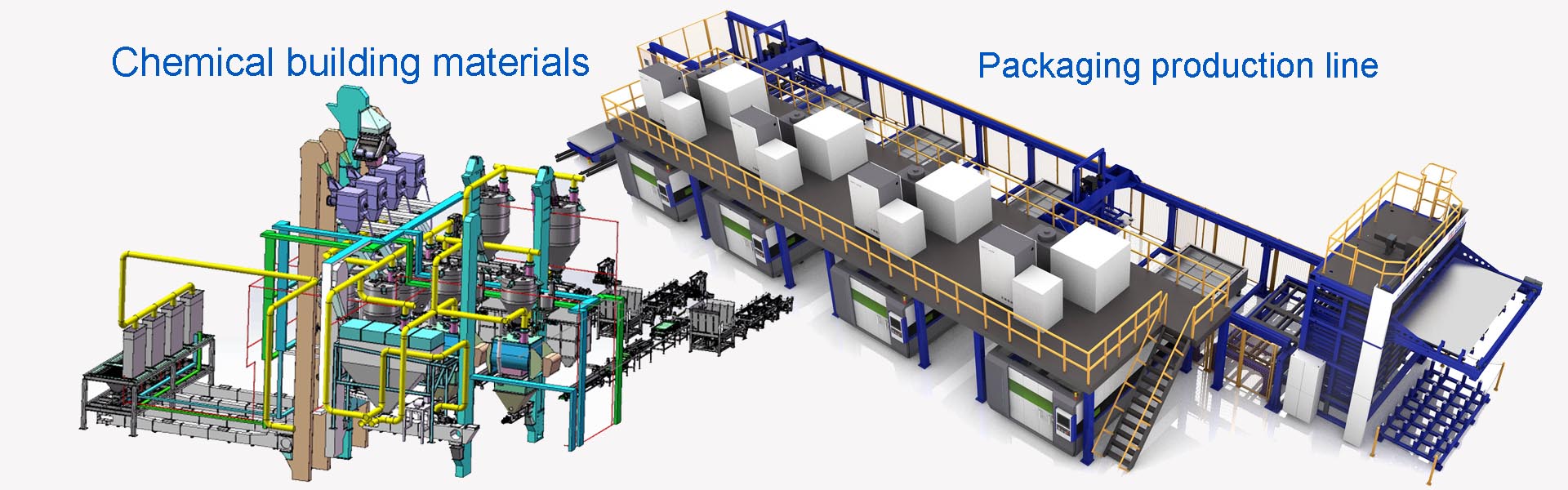

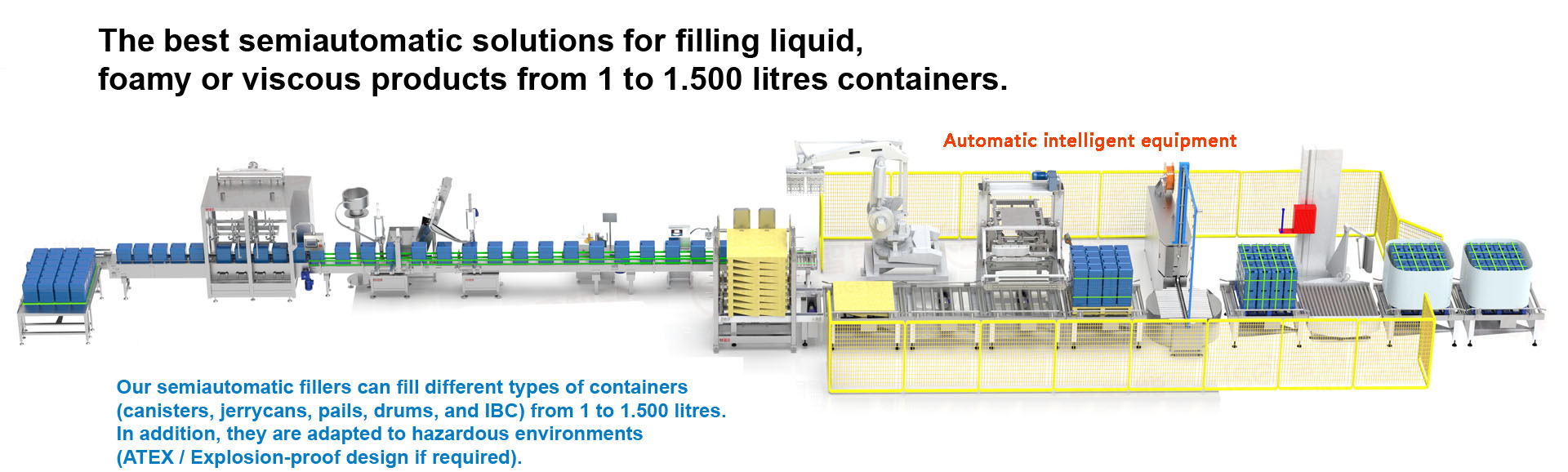

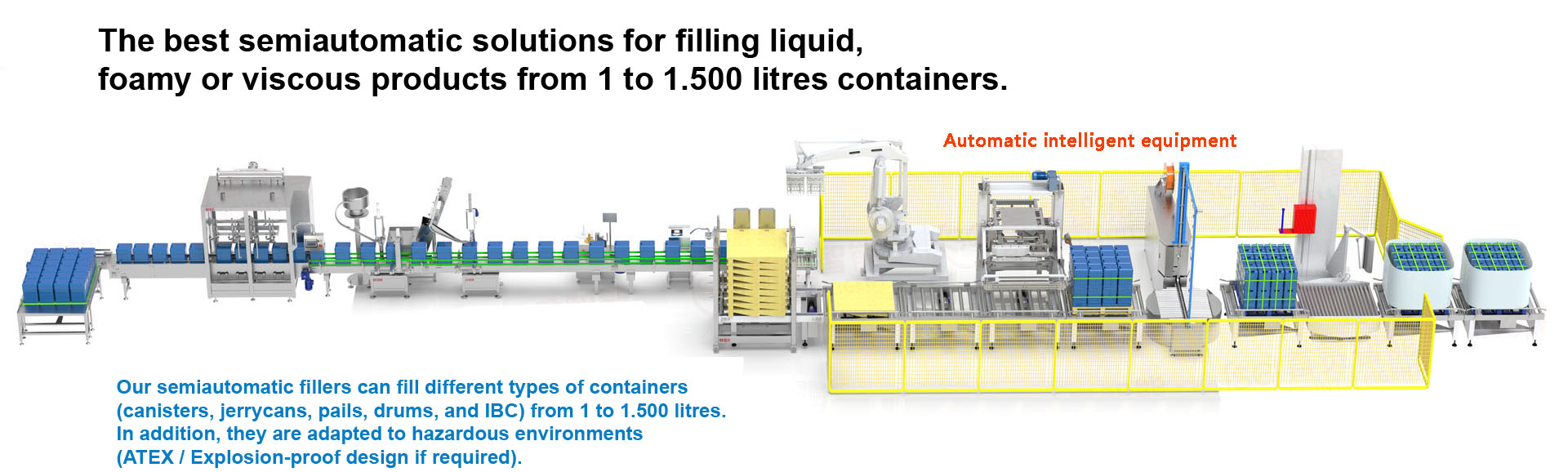

The Multifunctional Liquid Filling Machine is designed for safe, precise, and efficient filling of hazardous or flammable liquids (e.g., detergents, coatings, solvents, adhesives) into bottles, cans, pails, or drums. It integrates ATEX/IECEx explosion-proof certification, advanced flow control, and versatile compatibility with a wide range of container types and materials.

Key Features

Explosion-Proof Safety

ATEX/IECEx Certification: Safe for Zone 1/21 hazardous environments (Class I, II, III divisions).

Spark-Free Design: Pneumatic components, static-dissipative hoses, and grounding systems.

Nitrogen Blanketing (Optional): Inert gas purge to prevent oxidation or explosive atmospheres.

Precision Filling

Weighing System: Load cells with ±0.1% accuracy for consistent fill volumes.

Adjustable Flow Rate: Customizable via HMI (e.g., 0.5–10 L/min) to handle viscous or foaming liquids.

Anti-Drip Nozzle: Ceramic or stainless steel nozzle with pneumatic actuation for drip-free operation.

Multifunctional Compatibility

Container Types: Bottles, jars, cans, pails, drums, and IBC totes (customizable chucks).

Material Versatility: Suitable for detergents, coatings, solvents, oils, and high-viscosity fluids.

Capping/Sealing (Optional): Integrated modules for automatic capping or sealing.

Automation & Efficiency

Touchscreen HMI: Preset recipes, real-time monitoring, and diagnostics.

Conveyor Integration: Roller or belt conveyor for continuous feeding/unloading.

High-Speed Operation: Up to 60 containers/minute (depends on container size and material).

Corrosion Resistance

Construction: 304/316L stainless steel, PTFE seals, and FKM gaskets for chemical compatibility.

CIP Cleaning System: Automatic cleaning-in-place for hygiene and maintenance.

Customization Options

Vacuum Breaker: Prevents airlocks during filling of thixotropic or foaming liquids.

Barcode Scanning: Track batches, expiration dates, and ensure traceability.

Remote Control (Optional): Wireless operation via tablet or smartphone.

Technical Specifications

Filling Range: 50ml–20 liters (adjustable in 0.1mL increments).

Accuracy: ±0.1% of target volume/weight.

Materials: 304/316L stainless steel, ceramic nozzles, PTFE/FKM seals.

Safety Certification: ATEX, IECEx, CE.

Power Requirements: 220V/50Hz or 110V/60Hz (customizable).

Environment Rating: IP65 (dust and water resistant).

Operation Steps

Container Placement: Position the container under the nozzle via conveyor or manual loading.

Start Cycle: Initiate via HMI touchscreen, foot pedal, or automated sensors.

Flow Control: The pump dispenses liquid at a controlled rate, monitored by load cells or flow meters.

Nitrogen Purge (If Equipped): Inert gas blanketing to prevent foaming or contamination.

Shutdown: Automatic stop when target volume/weight is reached; nozzle retracts to prevent drips.

Cleanup: Nozzle purges automatically with solvent or air (optional CIP system).

Applications

Household Chemicals: Detergents, bleaches, and cleaning agents.

Industrial Coatings: Paints, varnishes, and protective coatings.

Adhesives & Sealants: High-viscosity glues and caulks.

Oils & Lubricants: Engine oils, greases, and industrial lubricants.

Pharmaceuticals: Syrups, oral suspensions, and topical gels.

Food & Beverage: Sauces, dressings, and viscous food additives.

Benefits

Safety First: ATEX/IECEx compliance ensures safe operation in hazardous environments.

Versatility: Handles a wide range of liquids, containers, and viscosities.

Precision & Speed: Accurate filling with minimal overfill or underfill; high throughput.

Low Maintenance: Robust construction and CIP compatibility reduce downtime.

Customization: Tailored for specific materials, container types, and flow requirements.

User-Friendly: Intuitive HMI and automated controls simplify operation and training.

Why Choose Us?

As a manufacturer, we specialize in explosion-proof filling solutions for hazardous and multifunctional applications. Our machines combine safety, precision, and versatility to meet your toughest challenges. Contact us for a tailored quote or consultation!

Immediate Order:

Website: http://m.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com