Dish Washing Liquid Filling Machines 18L 20L 25L Plastic Jerry Can Gallon Drum Cooking Oil Filling Machine Packing Line

、

、Dish Washing Liquid & Cooking Oil Filling Machine for 18L, 20L, 25L Jerry Cans and Drums

Overview:

A Dish Washing Liquid Filling Machine designed for 18L, 20L, 25L plastic jerry cans, gallon drums, and cooking oil containers is a versatile solution for packaging liquid products in large-volume containers. This machine can also be integrated into a packing line for automated capping, labeling, and sealing, making it ideal for medium to high-volume production of dishwashing liquid, cooking oil, chemicals, and other liquids.

Key Features:

Versatile Filling Capacity:

Container Sizes: Handles 18L, 20L, 25L, and larger containers (e.g., jerry cans, drums, or pails).

Adjustable Filling Volume: Easily set fill levels for different container sizes or product types via a user-friendly interface.

Precision Filling:

Weighing-Based or Level-Based Filling: Uses load cells or level sensors for accurate fill volumes (±0.1% error).

Drip-Free Nozzles: Prevents spills and overfilling, keeping the work area clean and reducing product waste.

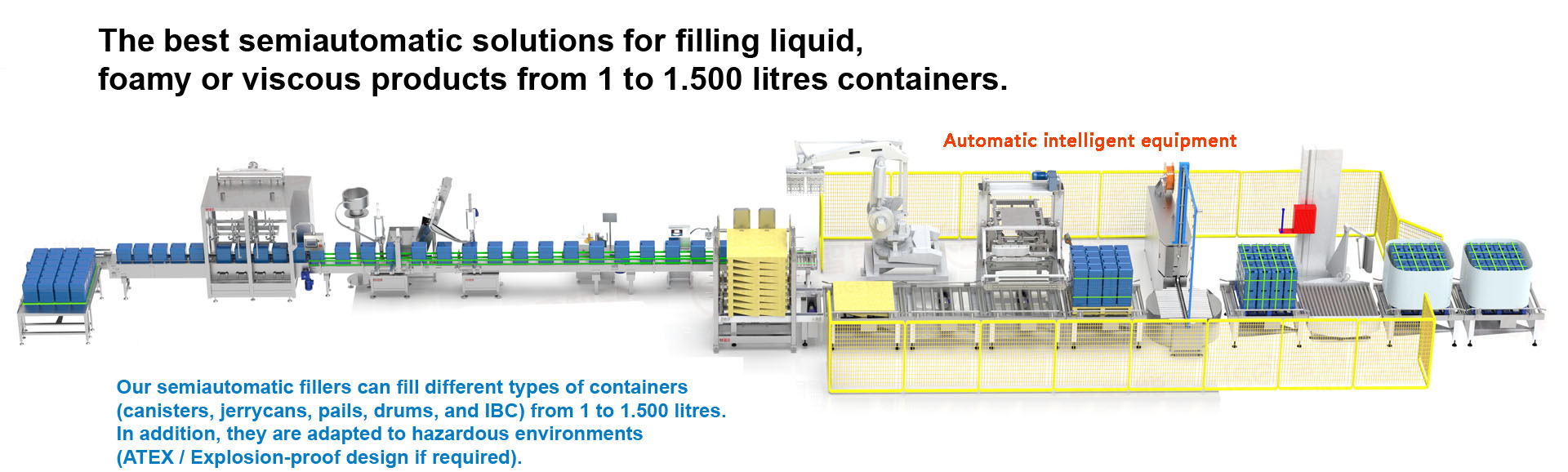

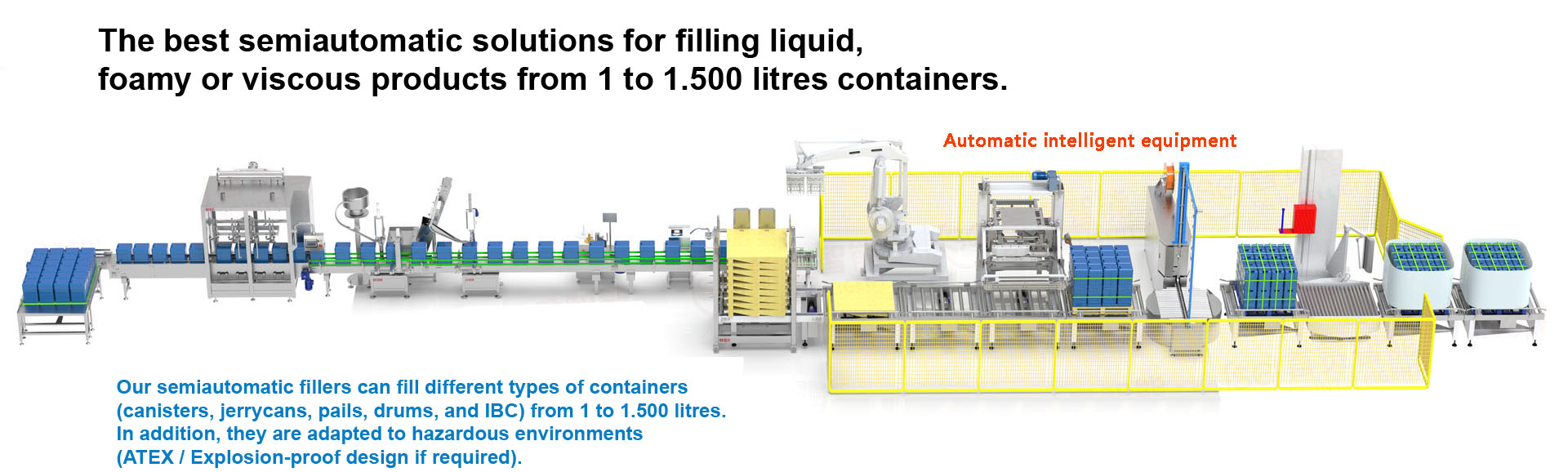

Semi-Automatic or Fully Automatic Options:

Semi-Automatic Operation: Manual placement and removal of containers.

Fully Automatic Line (Optional): Includes conveyors, capping machines, and labeling systems for seamless operation.

Hygiene and Safety:

Stainless Steel Construction: Made from food-grade stainless steel (304/316) for corrosion resistance and easy cleaning.

Sanitary Seals: Minimizes contamination risks, suitable for food-grade products like cooking oil.

Integrated Capping (Optional):

Automatically places and tightens caps on containers after filling, ensuring a secure seal.

User-Friendly Interface:

Touchscreen Control Panel: Intuitive controls for setting fill volumes, speeds, and capping parameters.

Pre-Set Recipes: Store multiple profiles for quick changeovers between products or container sizes.

Safety and Compliance:

Emergency Stop: Halts operation instantly in case of emergencies.

CE/ISO Compliance: Meets international safety and quality standards.

Optional Features:

Nitrogen Blanketing: Inert gas purging to prevent oxidation (useful for cooking oil).

Date Coding/Batch Numbering: Apply expiration dates, batch numbers, or barcodes for traceability.

Temperature Control: Maintain optimal product temperature during filling.

Applications:

Household Products: Dishwashing liquid, laundry detergent, multipurpose cleaners.

Food and Beverage: Cooking oil, sauces, syrups, edible oils.

Industrial Chemicals: Cleaning solutions, adhesives, motor oils.

Pharmaceuticals: Liquid medications or supplements (with material adjustments).

Automotive Fluids: Motor oils, greases, and other automotive fluids.

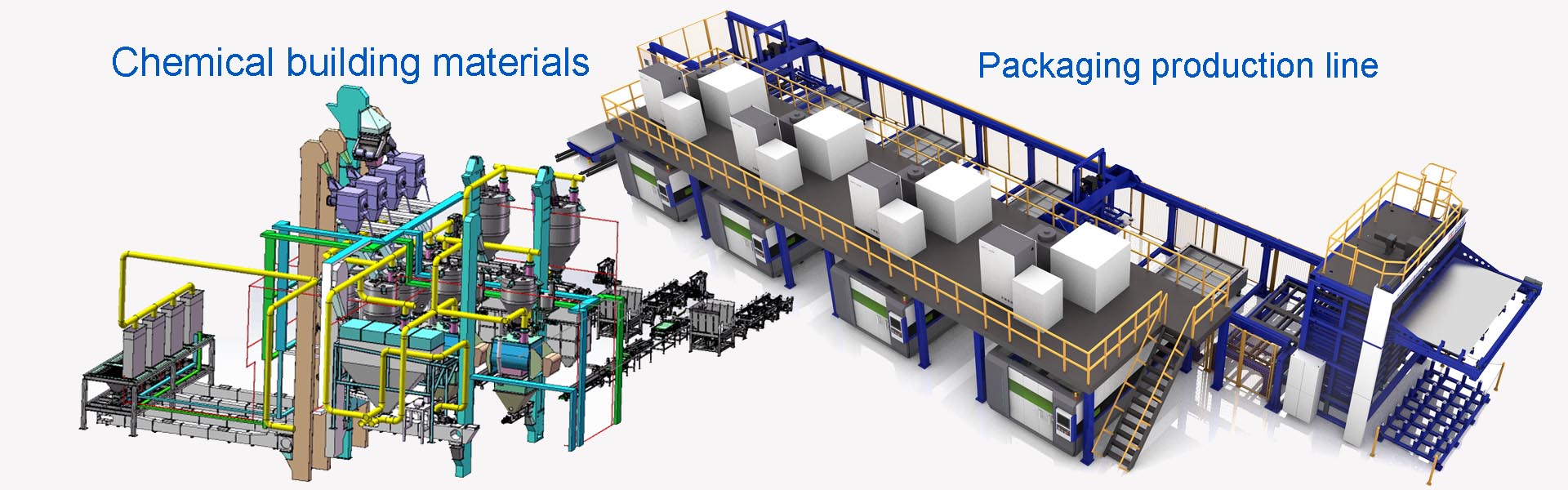

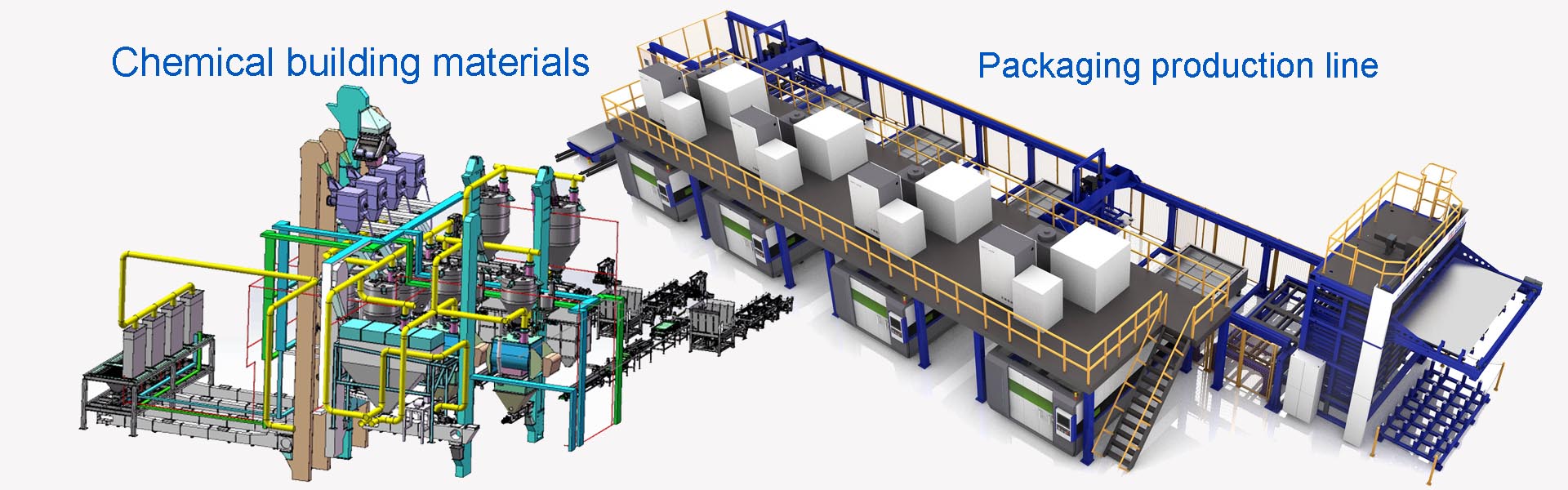

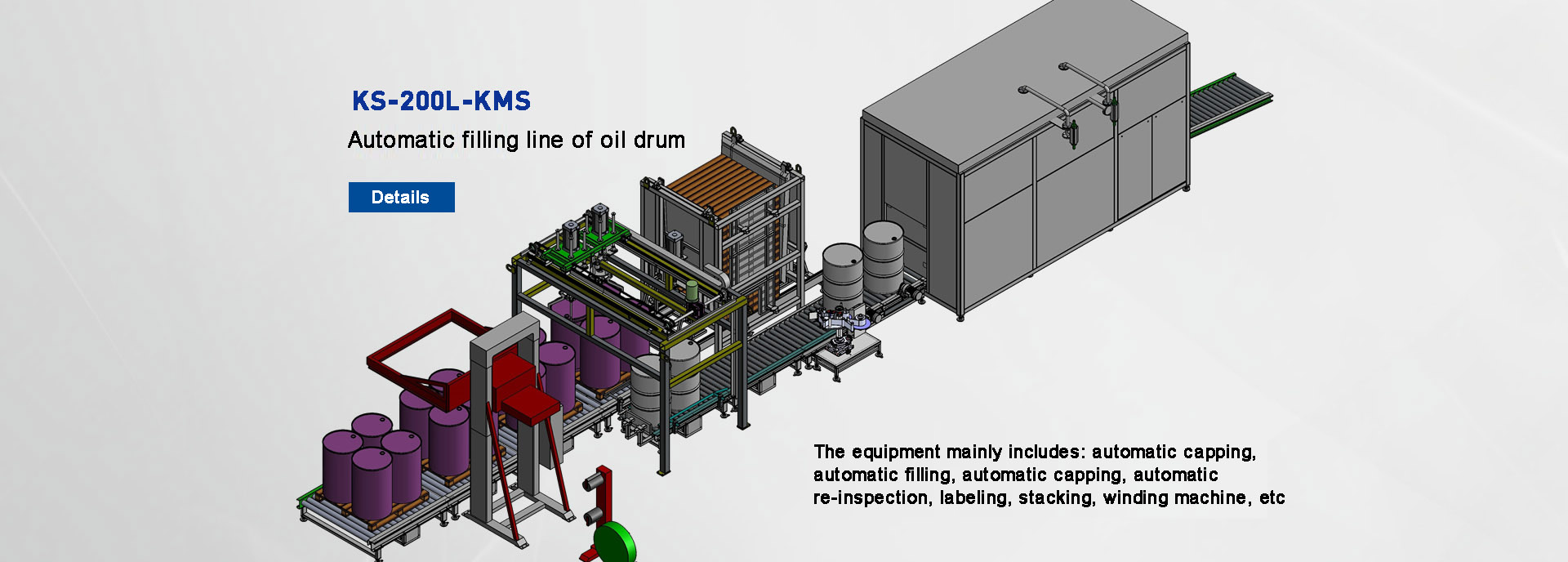

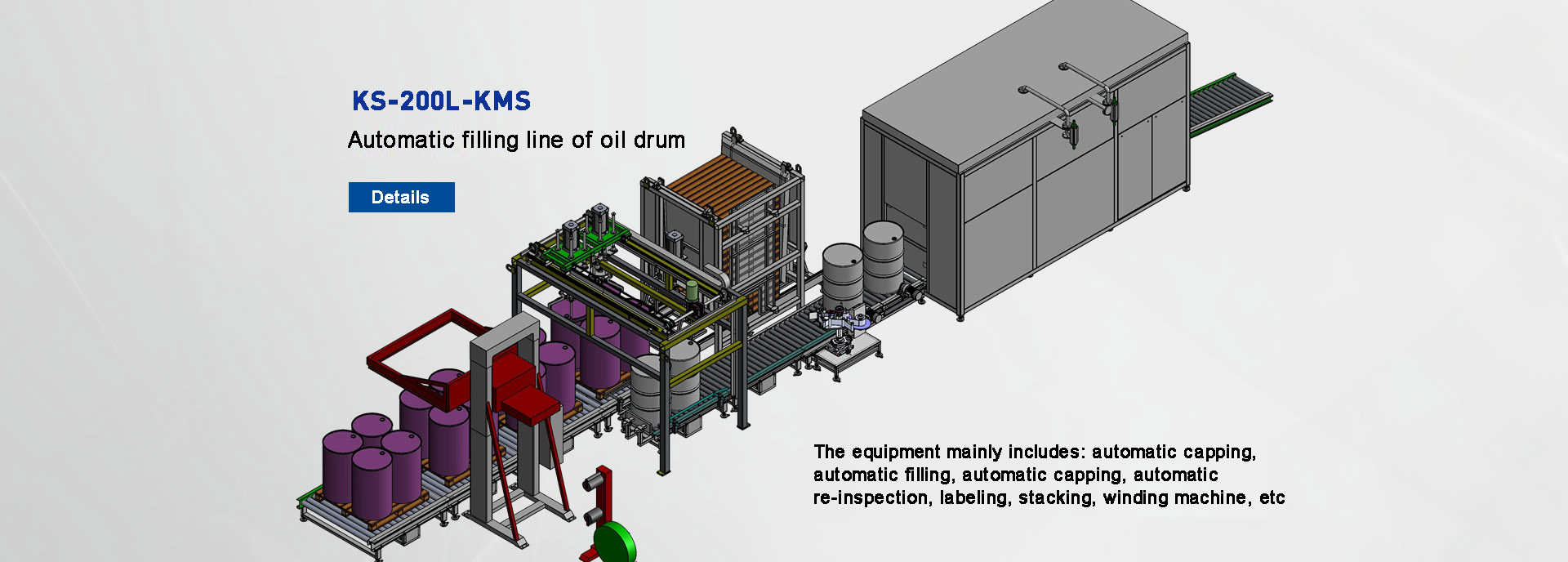

Packing Line Integration:

For a fully automated solution, the filling machine can be integrated into a packing line with:

Conveyors: For moving containers through the filling, capping, and labeling stations.

Capping Machine: Automatically seals containers with screw caps, snap caps, or press-on caps.

Labeling Machine: Applies product labels, expiration dates, or batch numbers.

Sealing Machine: Ensures airtight seals for long shelf life (optional for drums or pails).

Palletizing System: Automatically stacks filled containers onto pallets for easy shipping.

Benefits:

Cost-Effective: Reduces labor costs compared to manual filling.

Precision and Consistency: Accurate fill volumes minimize product waste.

Hygiene and Safety: Stainless steel construction ensures compliance with hygiene standards.

Versatility: Adaptable to various container sizes and materials.

Low Maintenance: Easy to clean and maintain, minimizing downtime.

Scalability: Start with a basic model and add upgrades as your production needs grow.

Operation Steps:

Container Placement: Manually place an empty container under the filling nozzle.

Automatic Filling: The machine detects the container and fills it to the pre-set volume.

Weight/Level Verification: Filling stops once the target volume is reached.

Automatic Capping (Optional): The machine seals the container with a cap.

Container Removal: Remove the filled container and place the next one.

Cleanup: Stainless steel surfaces make cleanup quick and easy.

Why Choose This Machine?

Dish Washing Liquid & Cooking Oil Filling Machine for 18L, 20L, 25L Jerry Cans and Drums

Overview:

A Dish Washing Liquid Filling Machine designed for 18L, 20L, 25L plastic jerry cans, gallon drums, and cooking oil containers is a versatile solution for packaging liquid products in large-volume containers. This machine can also be integrated into a packing line for automated capping, labeling, and sealing, making it ideal for medium to high-volume production of dishwashing liquid, cooking oil, chemicals, and other liquids.

Key Features:

Versatile Filling Capacity:

Container Sizes: Handles 18L, 20L, 25L, and larger containers (e.g., jerry cans, drums, or pails).

Adjustable Filling Volume: Easily set fill levels for different container sizes or product types via a user-friendly interface.

Precision Filling:

Weighing-Based or Level-Based Filling: Uses load cells or level sensors for accurate fill volumes (±0.1% error).

Drip-Free Nozzles: Prevents spills and overfilling, keeping the work area clean and reducing product waste.

Semi-Automatic or Fully Automatic Options:

Semi-Automatic Operation: Manual placement and removal of containers.

Fully Automatic Line (Optional): Includes conveyors, capping machines, and labeling systems for seamless operation.

Hygiene and Safety:

Stainless Steel Construction: Made from food-grade stainless steel (304/316) for corrosion resistance and easy cleaning.

Sanitary Seals: Minimizes contamination risks, suitable for food-grade products like cooking oil.

Integrated Capping (Optional):

Automatically places and tightens caps on containers after filling, ensuring a secure seal.

User-Friendly Interface:

Touchscreen Control Panel: Intuitive controls for setting fill volumes, speeds, and capping parameters.

Pre-Set Recipes: Store multiple profiles for quick changeovers between products or container sizes.

Safety and Compliance:

Emergency Stop: Halts operation instantly in case of emergencies.

CE/ISO Compliance: Meets international safety and quality standards.

Optional Features:

Nitrogen Blanketing: Inert gas purging to prevent oxidation (useful for cooking oil).

Date Coding/Batch Numbering: Apply expiration dates, batch numbers, or barcodes for traceability.

Temperature Control: Maintain optimal product temperature during filling.

Applications:

Household Products: Dishwashing liquid, laundry detergent, multipurpose cleaners.

Food and Beverage: Cooking oil, sauces, syrups, edible oils.

Industrial Chemicals: Cleaning solutions, adhesives, motor oils.

Pharmaceuticals: Liquid medications or supplements (with material adjustments).

Automotive Fluids: Motor oils, greases, and other automotive fluids.

Packing Line Integration:

For a fully automated solution, the filling machine can be integrated into a packing line with:

Conveyors: For moving containers through the filling, capping, and labeling stations.

Capping Machine: Automatically seals containers with screw caps, snap caps, or press-on caps.

Labeling Machine: Applies product labels, expiration dates, or batch numbers.

Sealing Machine: Ensures airtight seals for long shelf life (optional for drums or pails).

Palletizing System: Automatically stacks filled containers onto pallets for easy shipping.

Benefits:

Cost-Effective: Reduces labor costs compared to manual filling.

Precision and Consistency: Accurate fill volumes minimize product waste.

Hygiene and Safety: Stainless steel construction ensures compliance with hygiene standards.

Versatility: Adaptable to various container sizes and materials.

Low Maintenance: Easy to clean and maintain, minimizing downtime.

Scalability: Start with a basic model and add upgrades as your production needs grow.

Operation Steps:

Container Placement: Manually place an empty container under the filling nozzle.

Automatic Filling: The machine detects the container and fills it to the pre-set volume.

Weight/Level Verification: Filling stops once the target volume is reached.

Automatic Capping (Optional): The machine seals the container with a cap.

Container Removal: Remove the filled container and place the next one.

Cleanup: Stainless steel surfaces make cleanup quick and easy.

Why Choose This Machine?

This dish washing liquid and cooking oil filling machine offers a reliable, precise, and hygienic solution for packaging liquids in large containers. Its versatility, combined with optional automation features, makes it ideal for medium to high-volume production. Whether you’re filling dishwashing liquid, cooking oil, or industrial chemicals, this machine ensures consistent quality, reduces labor costs, and meets safety and hygiene standards. By integrating it into a packing line, you can further streamline your production process for maximum efficiency.

Immediate Order:

Website: http://m.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Multifunctional Automatic Metering Lubricant Filling Machine for 1-10L[2025-04-07]

-

Semi-Automatic Weighing and Filling Machine for Filling 18L Chemical Raw Materials/84 Disinfectant[2025-04-01]

-

Millet Oil filling machine _Non-Explosion Prooffilling machine[2025-07-29]

-

150kg Butane Gas Filling Machine with Carbon Steel[2025-04-23]