Fully Automatic Powder Valve Bag Filler Penuamtic Valve Bag Filling Packing Machine for Dry Mortar

Features

Our advanced design minimizes pollution: Employing low air pressure and instantaneous flow control technology, the system introduces minimal mixed air during material transport with air pressures between a mere 0.01-0.05Mpa. This careful regulation significantly curtails packaging process incidents like bulging, breakage, or leakage, effectively keeping dust in check. This innovative approach decreases pollution rates by an impressive 70%-90% compared to traditional packaging machines.

How to operate

Our operation process is streamlined for efficiency and precision. Materials journey into the weighing hopper via a state-of-the-art pneumatic gate feeding mechanism. The process is meticulously guided by a controller, which acts based on weight signals received from the sensor and operates per preset program parameters. Initially, materials undergo rapid feeding through a multi-speed system involving fast, medium, and slow phases. As the material weight reaches the set thresholds (target value minus specific measurement values), the system sequentially shifts from rapid to medium and finally slow feeding, executing precise weight adjustments. Upon reaching the final target weight, the feed door closes completely, signaling the completion of fixed value weighing. Post bag clamping, the discharge door on the weighing hopper opens automatically. Once the weight reverts to the zero setting, the door closes, allowing the material bag to descend onto the conveyor belt. This seamless transition leads to the sewing machine, finalizing the packaging before entering the next cycle, ensuring continuous efficiency.\

Touch screen PLC control

The machine features a cutting-edge, user-friendly touch screen interface paired with advanced PLC (Programmable Logic Controller) technology for robust control. It incorporates C3 level load cells and dual 6-bit high-precision weighing controllers, boasting a sampling speed of up to 128 times per second. Together with a frequency converter, these elements ensure unrivaled filling quality and accuracy.

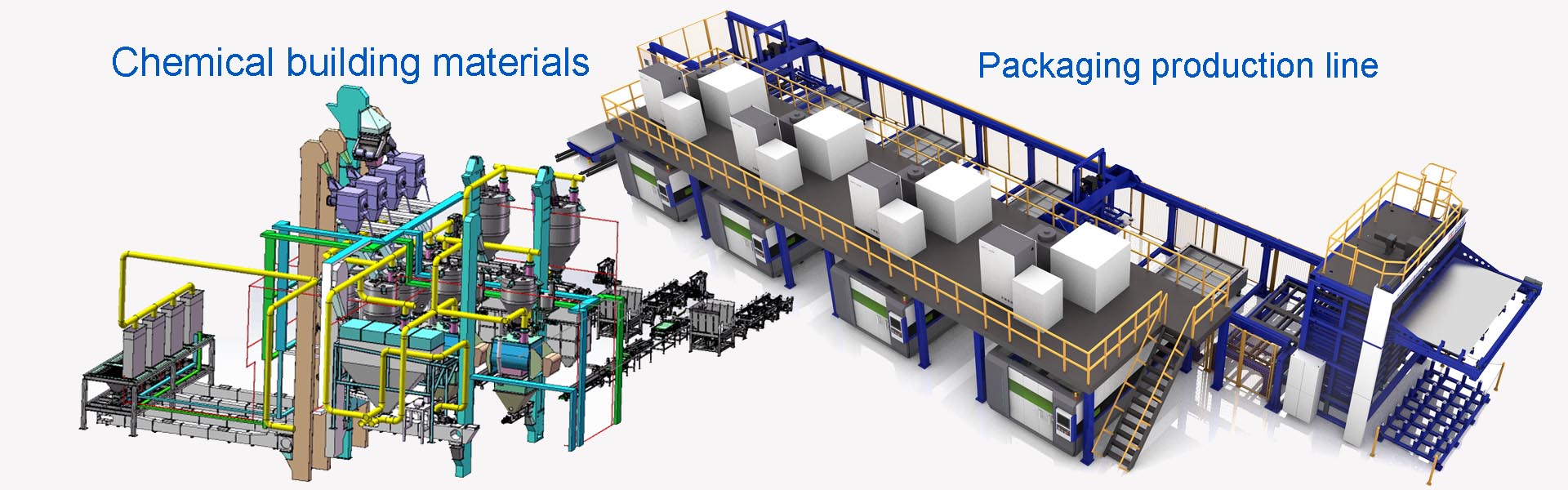

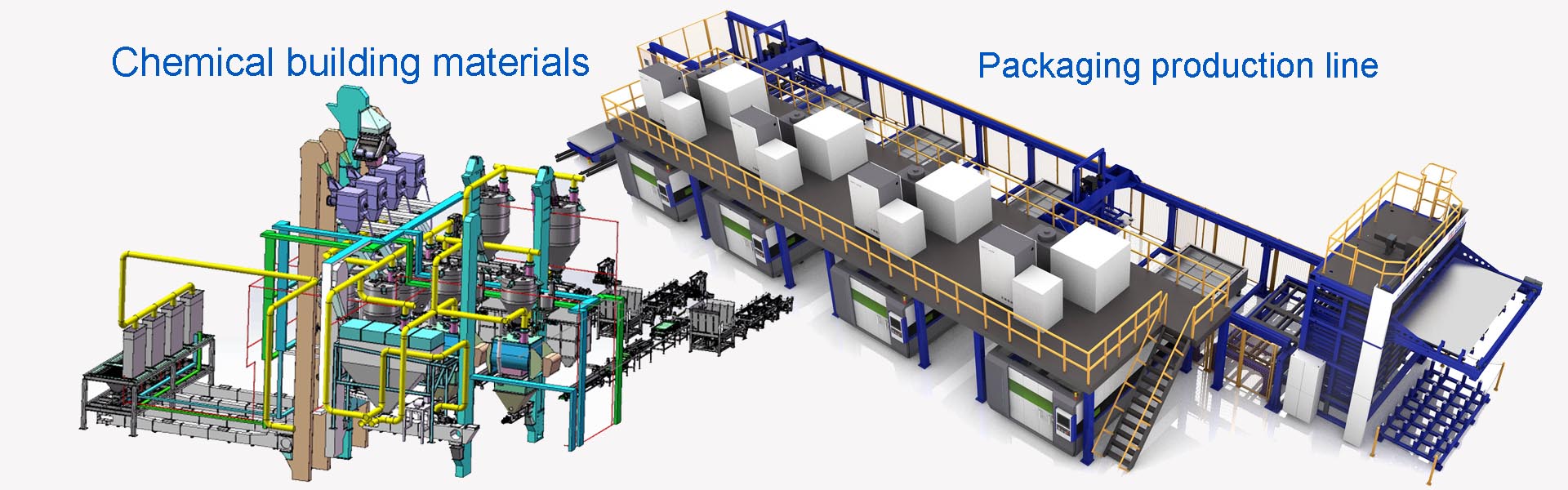

This sophisticated machine consists of several key components meticulously crafted for optimal functionality: the material inlet, a precise feeding mechanism (gate), the weighing hopper, a reliable bag clamping mechanism, a sturdy frame, an efficient air suction port, an advanced pneumatic system, sensitive sensors, and a comprehensive control box. Each part works in harmony to deliver superior performance.

-

Four Head packaging machine _Chemical Powder packaging machine [2025-09-10]

-

Metering Weighing packaging machine _Flake Materials packaging machine[2025-07-29]

-

Multi-Function packaging machine Technological innovations[2025-06-30]

-

416 Stainless Steel Lubricant Coating Filling Machine for 1-10L[2025-05-07]

-

Fruit Wine filling machine Machinery Co., Ltd.[2025-06-28]

-

Semi-Automatic Multi Functional Packaging Machine for Packaging Instant Coffee /Milk Powder/Dried[2025-07-04]

-

Liquid Surface Multi-Purposefilling machine _Liquid Surface Multi-Purposefilling machine _Liquid Surface Multi-Purposefilling machine [2025-09-08]