GZM-25 Weighing Filling Machine, a Filling Head with a Cap, Explosion-proof, Suitable for Chemical, Agriculture, Paint, Coating,

GZM-25 Weighing Filling Machine: Explosion-Proof, Versatile, and Efficient

Overview:

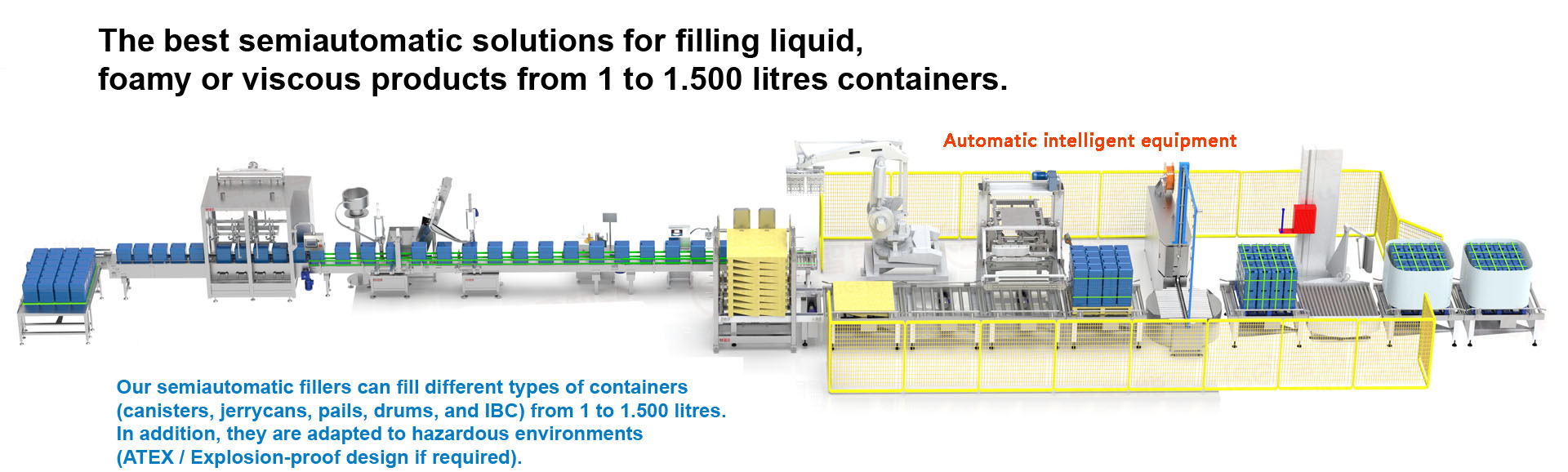

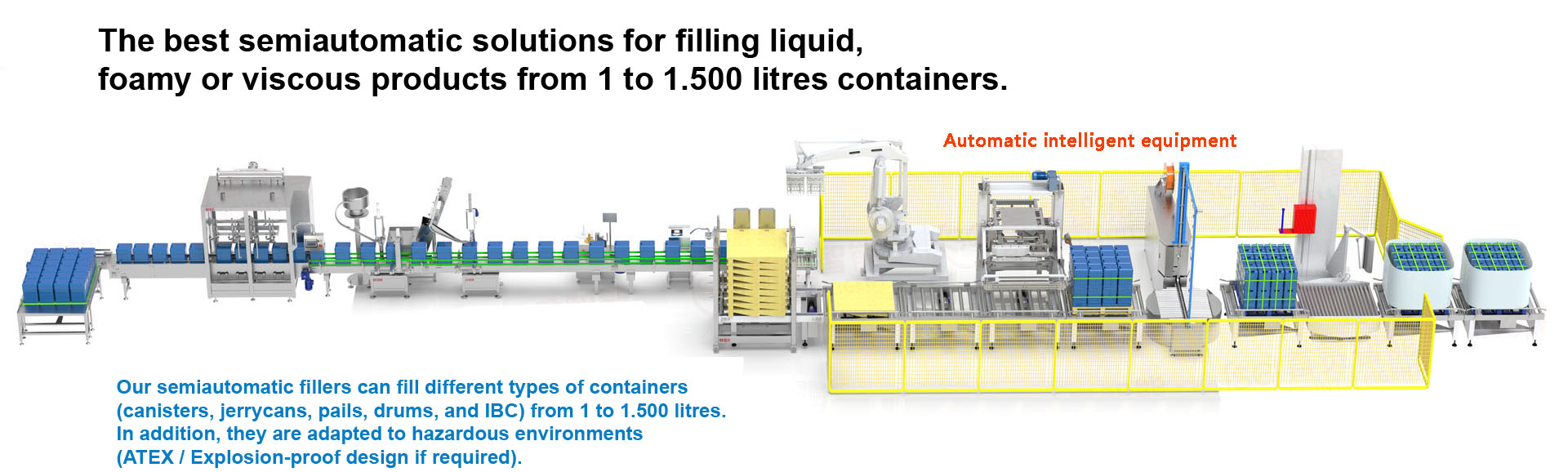

The GZM-25 Weighing Filling Machine is a high-performance, explosion-proof filling solution designed for industries requiring precise and safe handling of hazardous or flammable liquids. With its advanced weighing technology, explosion-proof certification, and versatile application capabilities, this machine is ideal for chemical, agricultural, paint, and coating industries. It ensures accurate filling, operator safety, and compliance with stringent industrial standards.

Key Features:

Explosion-Proof Design:

Certified Safety: Complies with ATEX, IECEx, or other relevant explosion-proof standards (depending on the region).

Suitable for Hazardous Environments: Safe for use in areas with flammable liquids or gases (e.g., chemical plants, petrochemical facilities, and paint manufacturing).

Intrinsically Safe Components: Electrical components and controls are designed to prevent sparks or heat generation.

Weighing Filling Technology:

High Precision: Uses load cells to measure weight, ensuring ±0.1% accuracy.

Adjustable Filling Range: Suitable for small to large volumes (e.g., 1L to 25L), with customizable presets for different products.

Tare Weight Function: Automatically accounts for container weight for precise net filling.

Versatile Applications:

Chemical Industry: Fills solvents, acids, bases, and other hazardous chemicals.

Agricultural Products: Ideal for pesticides, fertilizers, herbicides, and crop protectants.

Paint & Coatings: Accurately fills viscous and thixotropic products like paints, epoxies, and varnishes.

Oil & Gas: Suitable for lubricants, fuel additives, and industrial oils.

Filling Head with Cap:

Integrated Capping System: Seals containers automatically after filling, ensuring product integrity and reducing contamination risk.

Drip-Free Nozzles: Prevents spills and minimizes product waste.

Interchangeable Nozzles: Customizable for different container sizes and liquid viscosities.

User-Friendly Interface:

Touchscreen Control Panel: Easy to set target weights, monitor fill progress, and adjust parameters.

Pre-Set Recipes: Store frequently used fill settings for quick recall and reduced setup time.

Multi-Language Support: Enhances usability in diverse workplace environments.

Safety and Compliance:

Emergency Stop: Immediately halts operation in case of emergencies.

Lockable Controls: Prevents unauthorized changes to settings.

ATEX/IECEx Certification: Ensures compliance with explosive atmosphere regulations.

Durability and Low Maintenance:

Stainless Steel Construction: 304 or 316L stainless steel for corrosion resistance and longevity.

Chemical-Resistant Hoses and Seals: Made from materials like Viton, PTFE, or silicone to handle aggressive chemicals.

Quick-Release Parts: Hoses, nozzles, and drip trays can be easily removed for cleaning and maintenance.

Optional Features:

Nitrogen Blanketing: Inert gas purging to prevent oxidation, foaming, or evaporation (ideal for volatile products).

Data Logging: Records fill volumes, batch numbers, and dates for traceability and quality control.

Remote Monitoring: Integrates with SCADA systems for real-time monitoring and analytics.

Applications:

Chemical Manufacturing: Filling solvents, acids, bases, adhesives, and specialty chemicals.

Agricultural Products: Dispensing pesticides, fertilizers, herbicides, and crop protectants.

Paint & Coatings: Filling water-based, solvent-based, and high-viscosity coatings.

Oil & Gas: Handling lubricants, fuel additives, and industrial oils.

Pharmaceuticals: Filling liquid medications, supplements, and cosmetic products in hazardous environments.

Food & Beverage: Suitable for filling flammable or volatile food ingredients (e.g., alcohol-based products).

Operation Steps:

Container Placement: Manually place the container under the filling head.

Tare Weight Calibration: The machine automatically subtracts the container weight for precise net filling.

Target Weight Setting: Enter the desired fill weight on the touchscreen panel.

Start Filling: Activate the process via a foot pedal or button.

Precision Filling: The machine fills the container to the target weight, stopping automatically.

Capping: The integrated capping system seals the container (if equipped).

Container Removal: Remove the filled and capped container for further processing or storage.

Cleanup: Clean the machine after use to prevent cross-contamination and maintain hygiene.

Benefits:

Safety: Explosion-proof design ensures safe operation in hazardous environments.

Accuracy: Weighing technology provides precise fill volumes, reducing waste and product loss.

Versatility: Handles a wide range of liquids, from low-viscosity solvents to high-viscosity coatings.

Efficiency: Semi-automatic operation speeds up production compared to manual filling.

Compliance: Certified for use in explosive atmospheres, meeting global safety standards.

Customization: Optional features like nitrogen blanketing and data logging enhance functionality.

Low Maintenance: Stainless steel construction and quick-release parts simplify cleaning and upkeep.

Why Choose the GZM-25?

The GZM-25 Weighing Filling Machine is the ideal solution for industries that require precision, safety, and versatility in their filling operations. Its explosion-proof design, advanced weighing technology, and adaptability to various liquids make it perfect for chemical, agricultural, paint, and coating applications. Whether you’re filling hazardous chemicals, viscous coatings, or agricultural products, this machine delivers consistent performance, operator safety, and peace of mind.

Immediate Order:

Website: http://m.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Servo Motor Control Small Bottle Syrup Oral Liquid Filling Machine[2025-06-11]

-

Semi-Automatic Jam/Salad Dressing/Peanut Butter/Paint Cans Filling Machine for 5-30L[2025-05-30]

-

Vision-Guided Auto Nozzle Alignment Filling System 1-30L Bottles/Jerrycans ± 0.3% Accuracy[2025-07-03]

-

Stainless Steel 1000L Lubricant Grease Filling Equipment with PLC 3[2025-06-05]