Automated Drum Filling Machine Reliable, Fast & Spillage-Free Industrial Filling

Automated Drum Filling Machine: Reliable, Fast, & Spillage-Free Industrial Filting

Overview

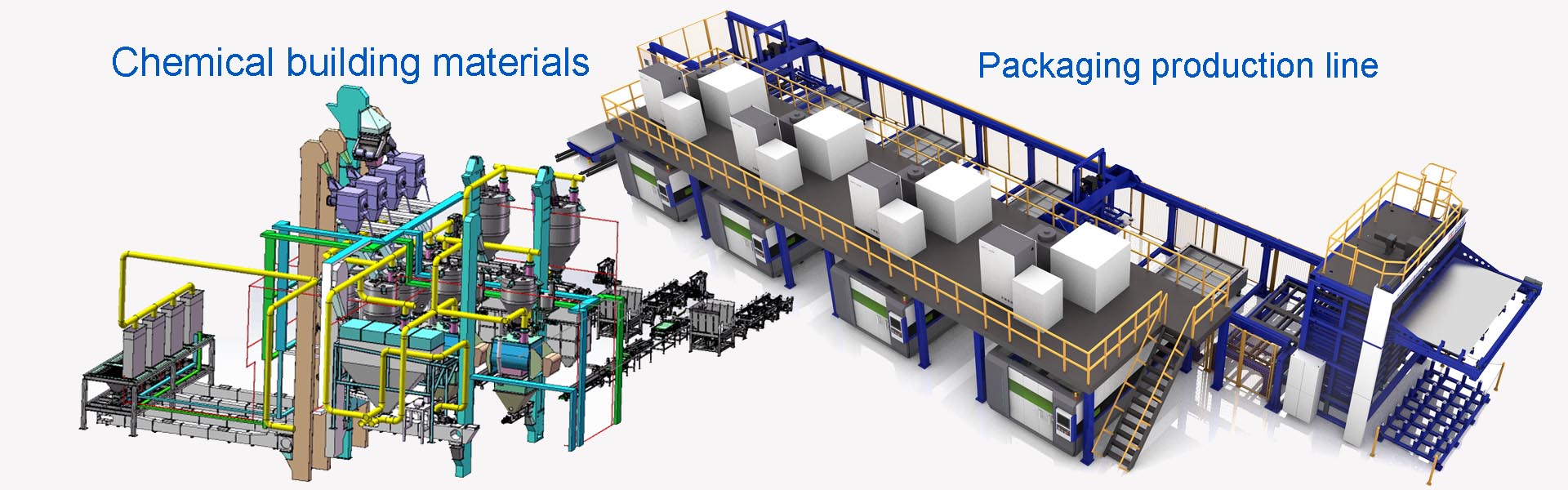

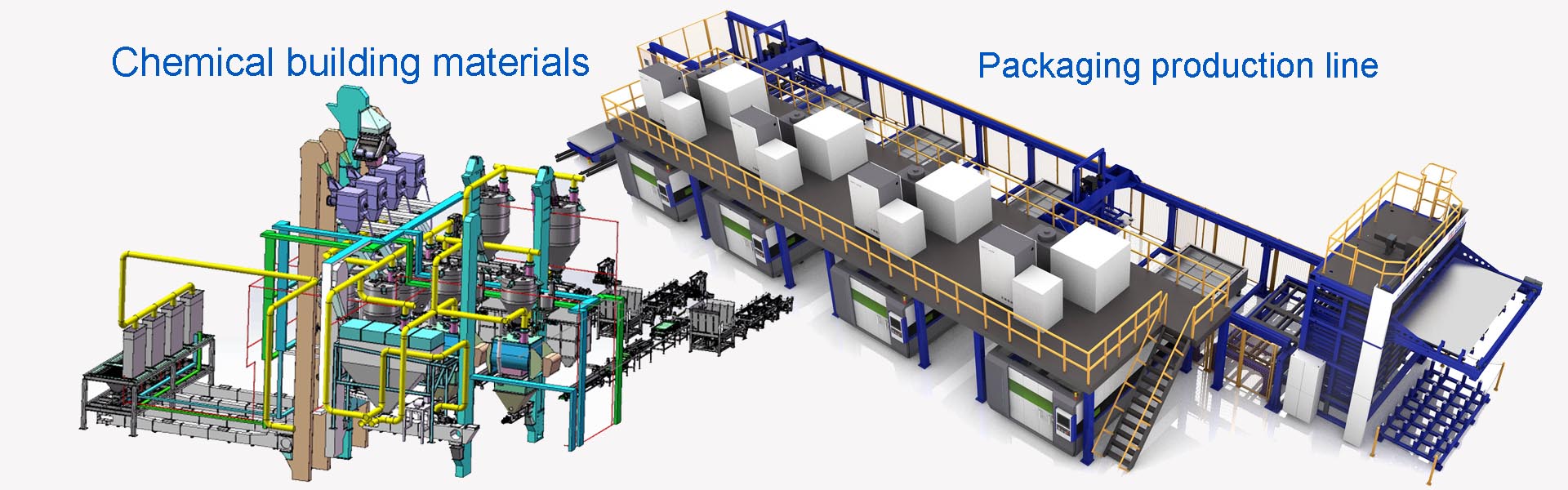

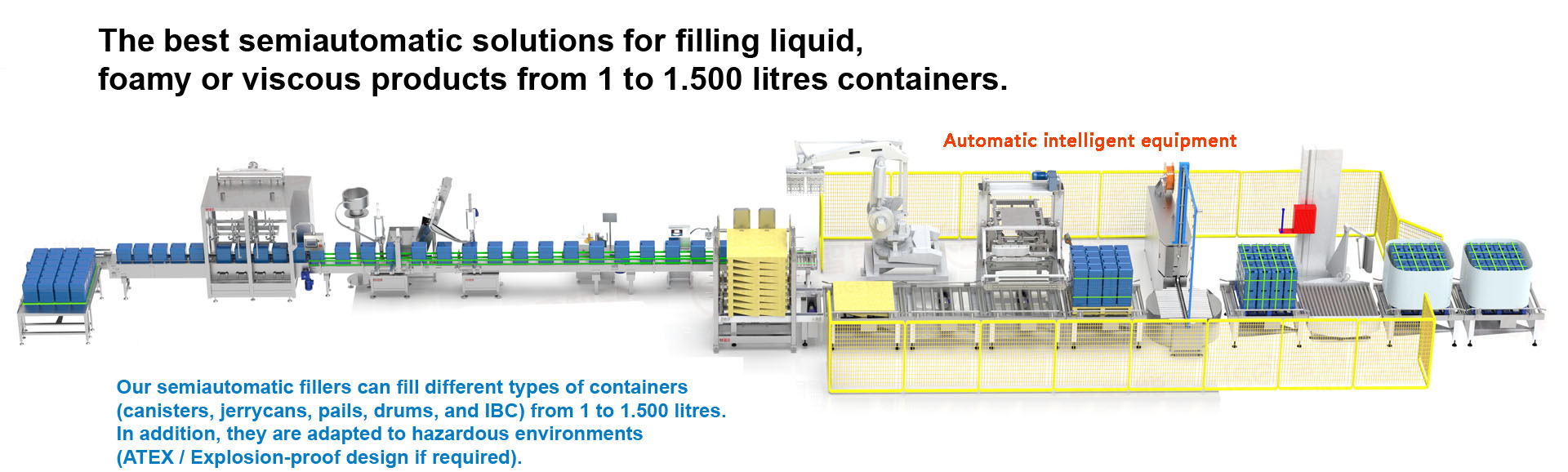

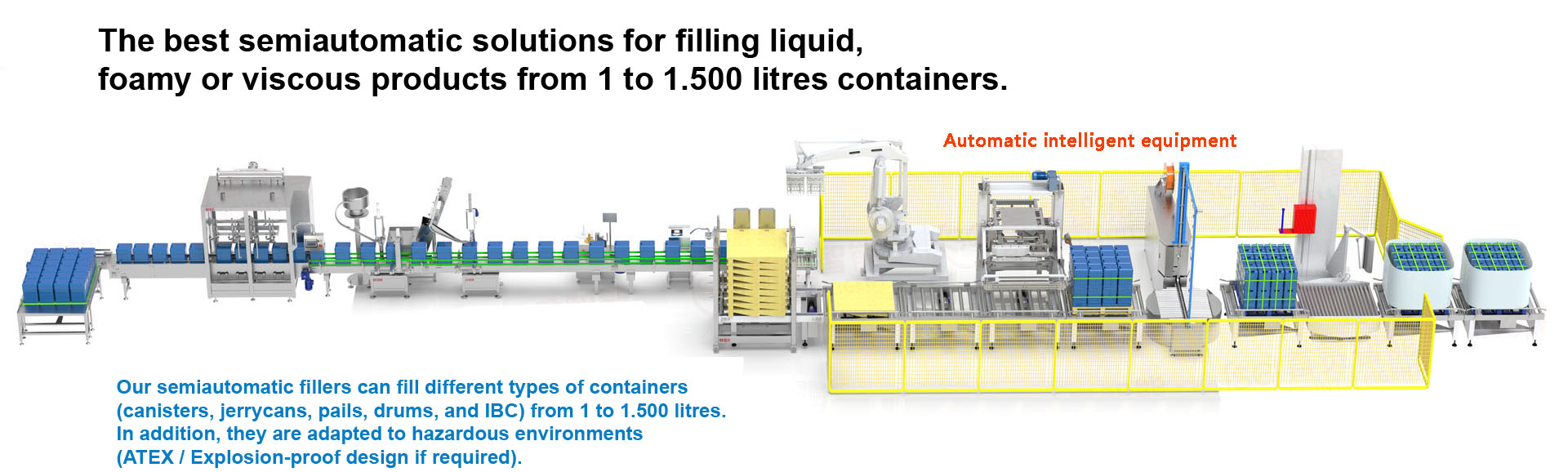

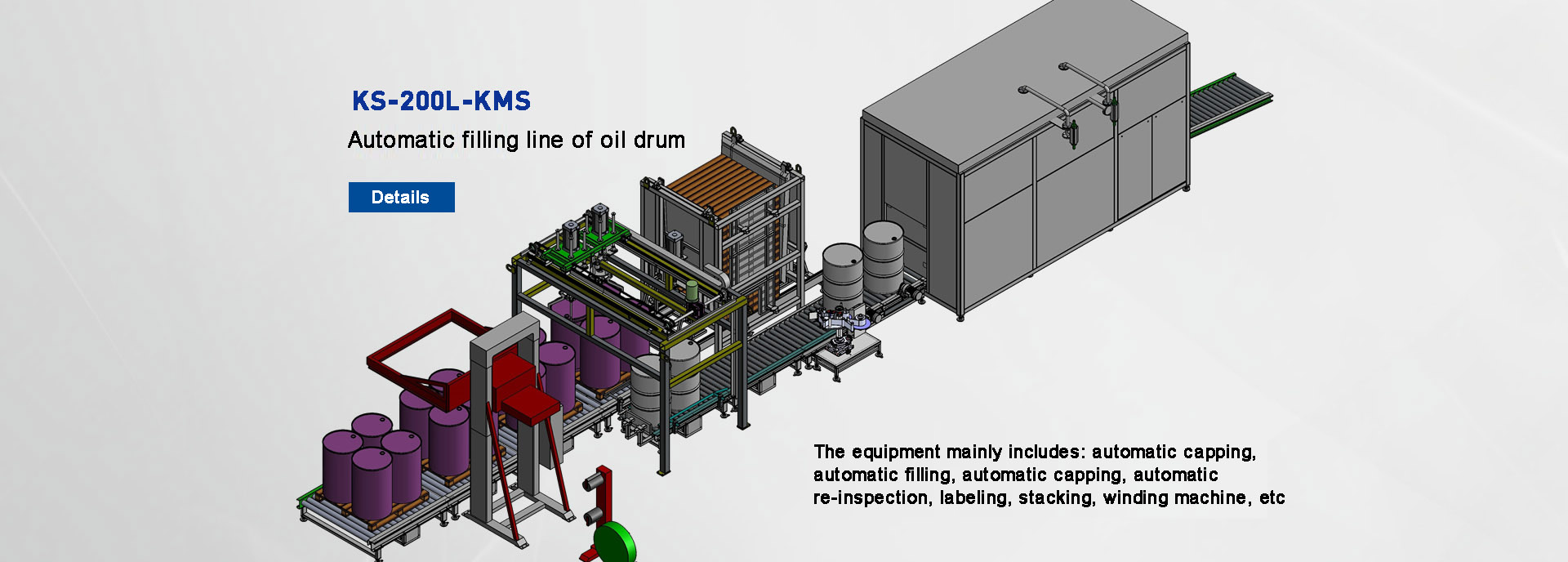

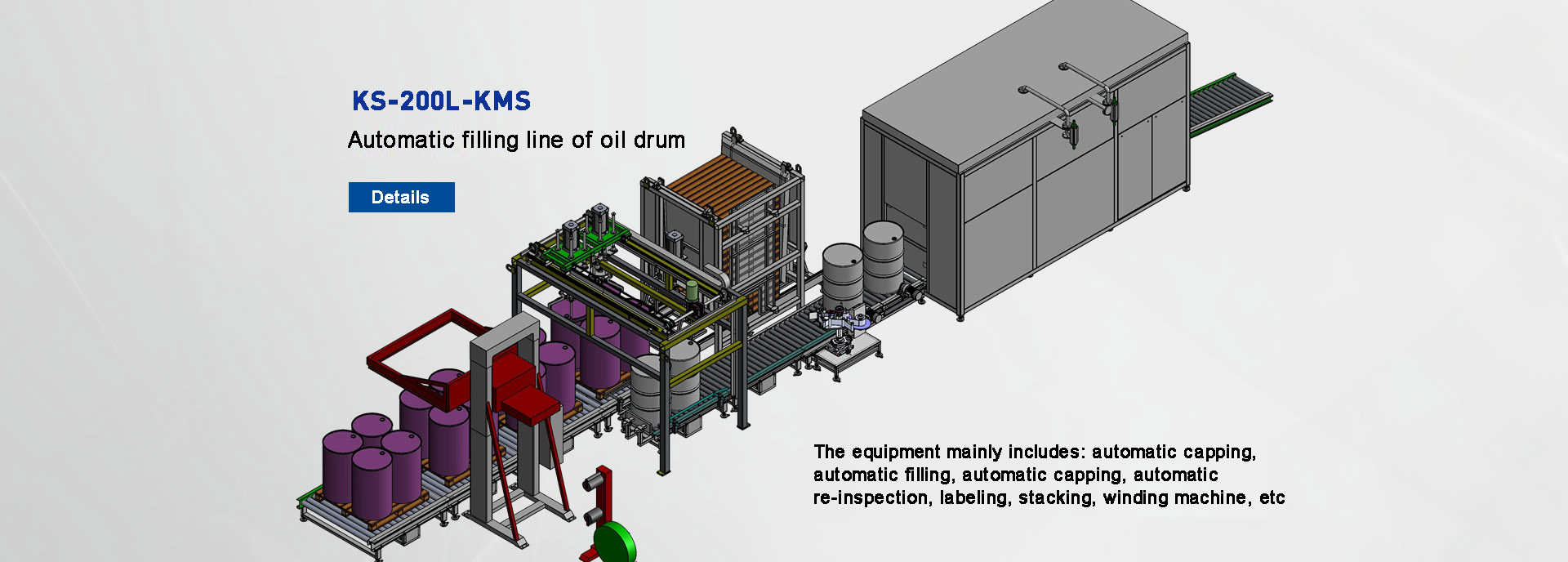

The Automated Drum Filling Machine is designed for high-speed, precision filling of liquids into drums, IBC totes, and intermediate bulk containers (IBCs). Ideal for industrial applications requiring reliability, speed, and zero spillage, this machine integrates advanced automation, safety features, and customizable options to meet diverse needs.

Key Features

Speed & Efficiency

High Throughput: Fills up to 60 drums/hour (depending on viscosity and container size).

Continuous Operation: Automated drum indexing and conveyor systems minimize downtime.

Quick Changeover: Tool-free adjustments for different drum sizes (20L–200L).

Precision Filling

Weight-Based Accuracy: ±0.1% accuracy with integrated load cells and HMI control.

Volumetric Mode: Adjustable flow rates for consistent fill levels.

Drip-Free Nozzles: Prevents leaks and reduces product waste.

Zero Spillage Technology

Closed-Loop System: Automatic nozzle retraction and sealing after filling.

Vacuum Purging: Removes residual product from hoses to prevent dripping.

Overfill Protection: Auto-stop function to avoid excess product loss.

Safety & Compliance

ATEX/IECEx Certified: Safe for hazardous environments (Class II, Division 1).

Static Grounding: Automated grounding of drums to eliminate static sparks.

Interlocked Guards: Prevents accidental operator access during operation.

Customizability

Viscosity Handling: Suitable for thin liquids (e.g., water) to high-viscosity products (e.g., greases, adhesives).

Material Compatibility: Stainless steel (304/316L), Hastelloy, or PTFE-lined components for corrosive chemicals.

Capping & Sealing: Optional automated capping, tamper-evident seals, and labeling modules.

Technical Specifications

Filling Capacity: 20L–200L drums, IBC totes, or custom containers.

Accuracy: ±0.1% (weight-based) or ±0.5% (volumetric).

Viscosity Range: Up to 5,000 cP (customizable for higher viscosities).

Power: Explosion-proof motors (220V/50Hz or 110V/60Hz).

Certifications: ATEX, CE, ISO, OIML-R60 (weighing systems).

Applications

Chemicals & Petrochemicals: Solvents, oils, resins, and flammable liquids.

Food & Beverage: Edible oils, sauces, syrups, and bulk ingredients.

Pharmaceuticals: APIs, suspensions, and sterile liquids (optional cleanroom design).

Industrial Lubricants: Greases, cutting fluids, and heavy oils.

Paints & Coatings: Solvent-based, water-based, or high-viscosity formulations.

Operation Steps

Drum Placement: Operator positions an empty drum under the filling nozzle (manually or via conveyor).

Automatic Grounding: Static elimination system grounds the drum to prevent sparks.

Precision Filling: Weight-based or volumetric dispensing with adjustable flow rate.

Nozzle Retraction: Automated nozzle lift and seal to prevent drips.

Optional Capping/Sealing: Apply tamper-evident seals or closures.

Cycle Completion: Filled drum moves to next stage (e.g., labeling, palletizing).

Optional Features

Conveyor Systems: Roller or belt conveyors for seamless drum handling.

Vapor Recovery: Enclosed fill heads with carbon filters to trap fumes.

Data Logging: USB/Ethernet export for batch tracking and compliance.

Remote Control: Start/stop cycles from a safe distance (explosion-proof remote).

Nitrogen Overlay: Inert gas purging to protect products from oxidation.

Benefits

Maximized Productivity: High-speed filling with minimal downtime.

Cost Efficiency: Reduced product waste and labor costs.

Regulatory Compliance: Meets global standards for hazardous materials and industrial use.

Versatility: Customizable for viscosity, container size, and closure types.

Low Maintenance: Robust construction with easy-to-clean components.

Why Choose This Machine?

The Automated Drum Filling Machine delivers unmatched speed, accuracy, and safety for industrial liquid filling applications. Whether you’re processing chemicals, food products, or pharmaceuticals, its advanced automation, zero-spillage technology, and customizable features ensure reliable performance in demanding environments.

Contact us today for a tailored solution!

Immediate Order:

Website: http://m.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com