High Speed 50kg Dry Mixed Mortar Valve Bag Packing Machine with Bag Drop Device

High-Speed 50kg Dry Mixed Mortar Valve Bag Packing Machine with Bag Drop Device

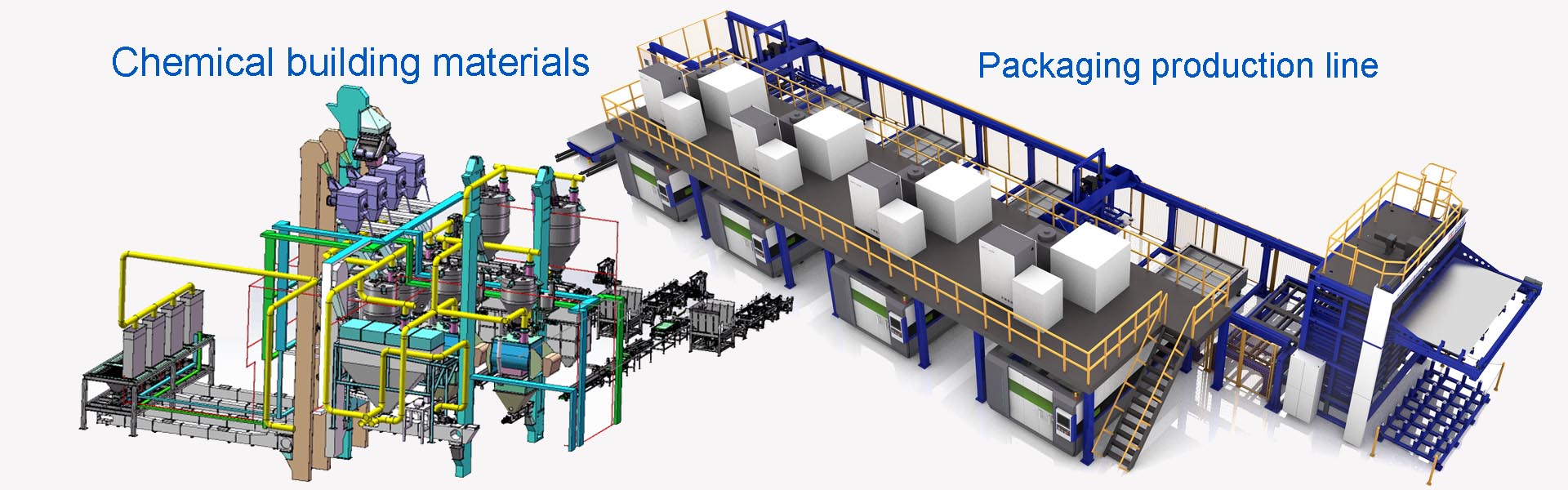

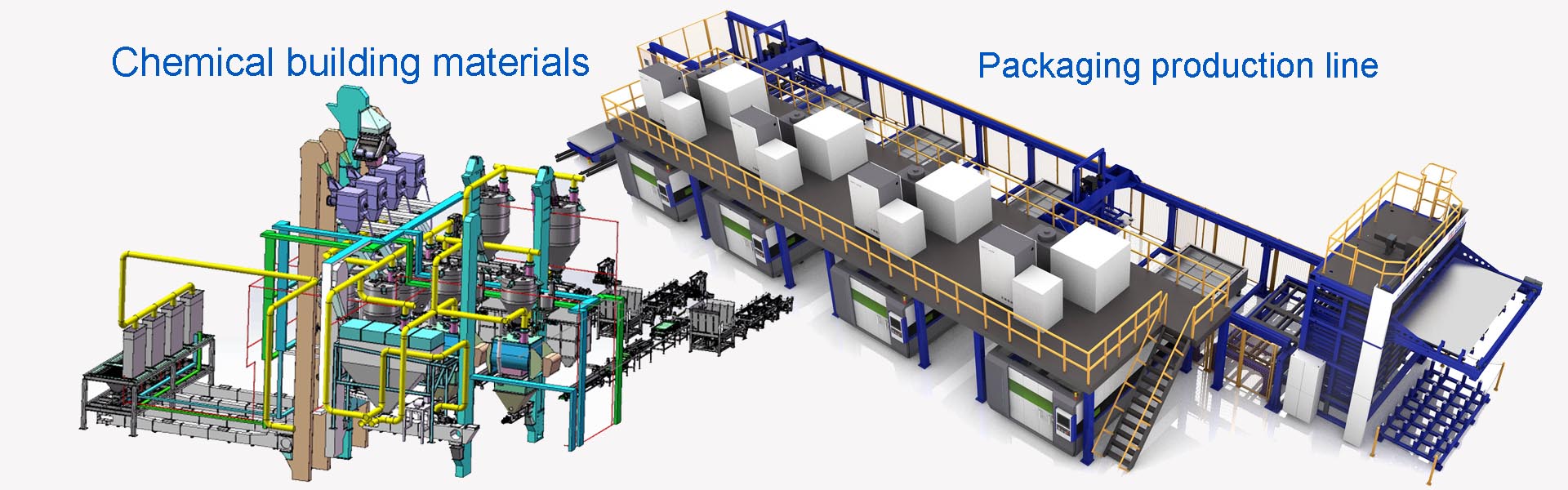

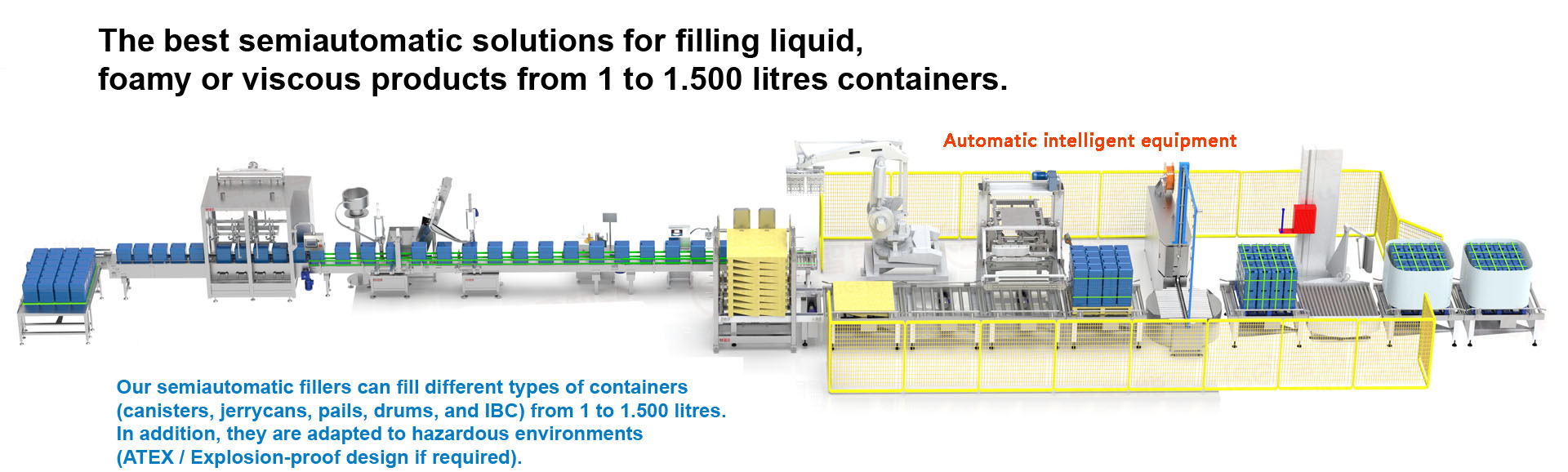

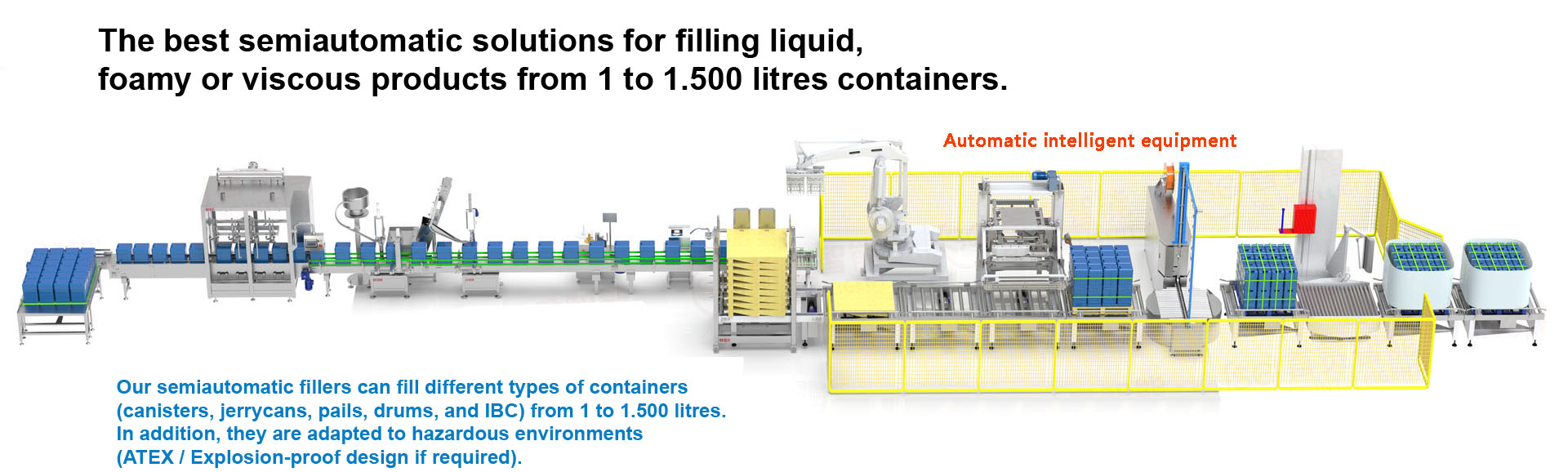

A High-Speed 50kg Dry Mixed Mortar Valve Bag Packing Machine with Bag Drop Device is a specialized automated system designed for efficient, precise, and dust-free packaging of dry mixed mortar (e.g., cement, sand, and additive mixtures) into 50kg valve bags. This machine is widely used in the construction, building materials, and industrial sectors for packaging dry powder or granular materials. Below is a detailed overview of its key features, benefits, and applications.

Key Features:

High-Speed Packing:

Automated Filling: Capable of filling 50kg valve bags at speeds of up to 12–15 bags per minute, depending on the model.

Precision Weighing: Equipped with load cells and a digital weighing system to ensure accurate fill weights (±50g tolerance).

Valve Bag Compatibility:

Valve Bag Spout Filling: Designed specifically for valve bags, which are heat-sealed after filling to prevent spillage and contamination.

Bag Drop Device: Automates the process of dropping empty valve bags onto the filling spout, reducing manual labor and increasing efficiency.

Dust Control:

Dust Extraction System: Integrated with a dust collection mechanism to minimize airborne particles during filling.

Sealed Filling Area: Encloses the filling spout to prevent dust emissions and maintain a clean working environment.

Automated Operation:

PLC Control: Manages the entire packing process, from bag drop to filling and sealing.

HMI Touchscreen: User-friendly interface for setting target weights, monitoring production, and troubleshooting.

Bag Drop Device:

Automatic Bag Placement: Drops empty valve bags onto the filling spout, ensuring consistent and precise positioning.

Bag Detection Sensors: Ensures bags are correctly placed before filling begins.

Versatility:

Adjustable Filling Speeds: Variable speed control to accommodate different product densities and bag sizes.

Multi-Product Compatibility: Suitable for dry mixed mortar, cement, sand, plaster, and other powdered or granular materials.

Safety Features:

Emergency Stop: Instant shutdown in case of emergencies.

Overload Protection: Prevents damage to the machine or bags due to excessive filling.

Dust-Tight Enclosures: Protects operators and machinery from dust exposure.

Data Logging and Traceability:

Batch Identification: Records fill weights, times, and batch numbers for traceability.

USB/Ethernet Ports: Exports data for compliance with regulatory requirements or inventory management.

Integration Capabilities:

Upstream Integration: Connects with mixers, silos, or conveyor systems for a fully automated workflow.

Downstream Integration: Compatible with palletizers, sealing machines, and labeling systems for seamless operation.

Benefits:

High Efficiency:

Automated bag drop and filling significantly reduce labor costs and increase throughput.

Accuracy and Consistency:

Precision weighing ensures each bag is filled to the exact target weight, reducing waste and ensuring product quality.

Dust-Free Operation:

Integrated dust extraction and sealed filling areas minimize airborne particles, improving operator safety and workplace cleanliness.

Safety:

Advanced safety features (e.g., emergency stop, overload protection) protect operators and prevent accidents.

Versatility:

Suitable for a wide range of dry powdered or granular materials, making it a flexible solution for various industries.

Cost Savings:

Minimizes product loss, reduces labor costs, and lowers maintenance expenses due to robust design and automation.

Scalability:

Ideal for small, medium, or large-scale operations, with options for semi-automatic or fully automatic configurations.

Applications:

Construction Materials:

Packaging dry mixed mortar, cement, sand, and plaster for use in construction projects.

Building Materials Manufacturing:

Bottling dry powders or granular materials for distribution to retailers or contractors.

Industrial Use:

Packaging chemicals, fertilizers, or other dry granular products for industrial applications.

Distribution and Logistics:

Preparing 50kg valve bags for export or transport to other facilities.

Why Choose This Machine?

Unmatched Speed and Accuracy: High-speed filling with precision weighing ensures efficient and consistent packaging.

Dust-Free Operation: Integrated dust control and sealed filling areas protect operators and maintain a clean environment.

Fully Automated Workflow: From bag drop to filling and sealing, this machine minimizes manual labor and increases productivity.

Safety and Compliance: Advanced safety features and data logging ensure adherence to regulatory requirements.

Customization: Tailored to meet specific industry requirements, such as dust extraction, bag drop devices, or multi-product support.

Scalability: Suitable for small-scale or large-scale operations, with options for integration into broader production lines.

Invest in a High-Speed 50kg Dry Mixed Mortar Valve Bag Packing Machine with Bag Drop Device to streamline your operations, ensure product quality, and enhance safety. This system combines speed, accuracy, and automation to meet the demands of modern construction and building materials industries.

Immediate Order:

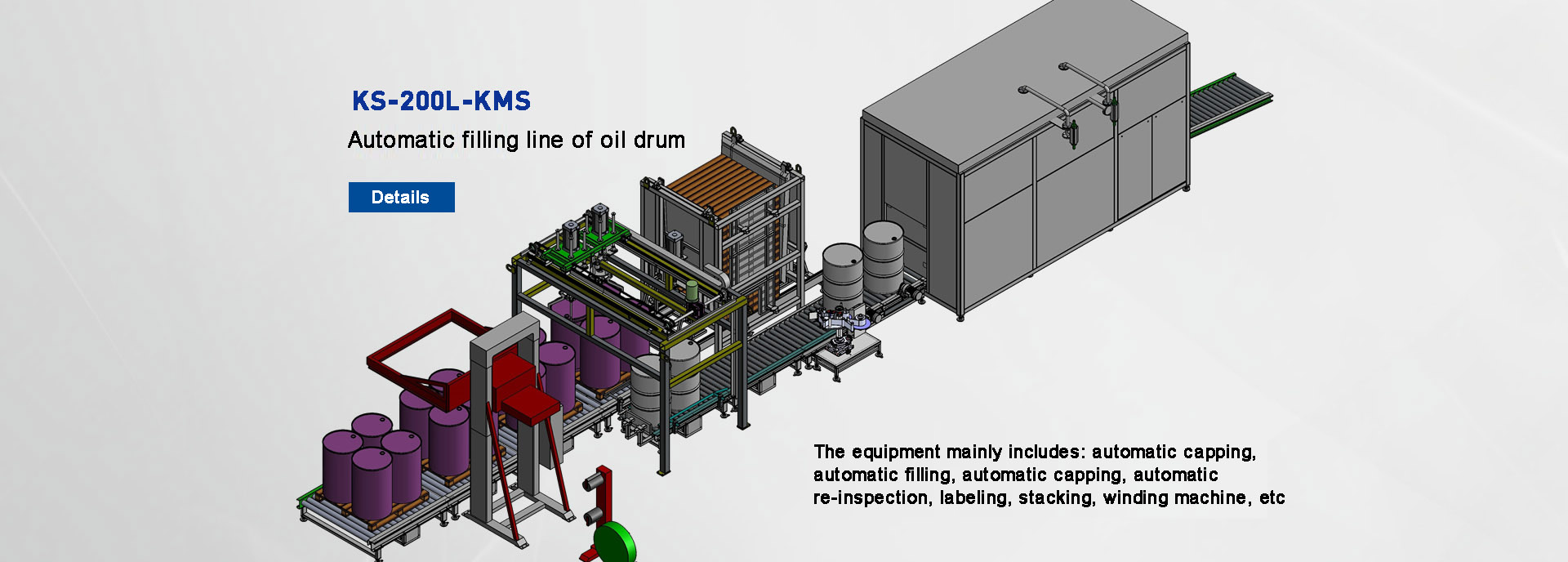

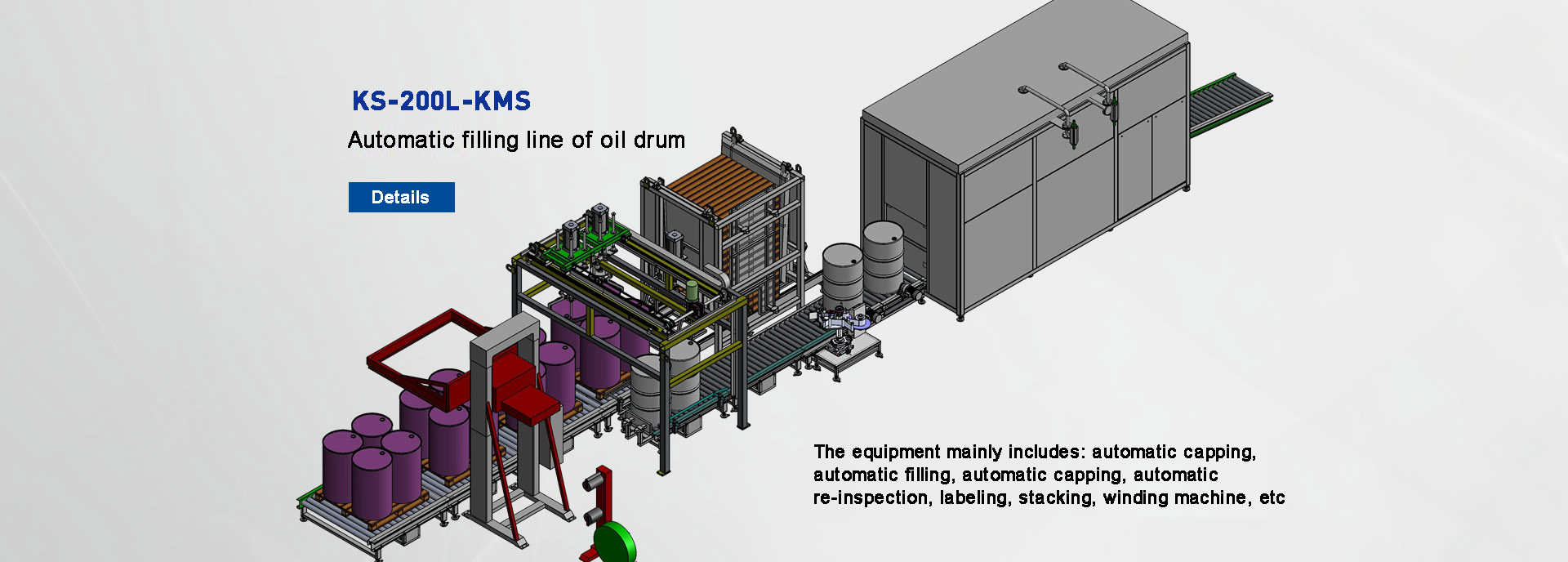

Website: http://m.22694.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Semi-Automatic Industrial Raw Juice Paste Concentrate Drum Filling Machine[2025-04-12]

-

Fresh Orange Juice Production Line Juice Washing Filling Roll Film Filling Machine[2025-04-12]

-

Full Automatic Complete Turnkey 5gallon Bottle Filling Machine[2025-06-07]

-

Putty Filling Machine Filling Machine Made in China[2025-06-12]