Automatic Quantitative Paint Filling Machine - 200kg Filler

Product Introduction: 200kg Automatic Quantitative Liquid Filling Machine

Precision, Speed, and Safety for Coatings & Chemical Manufacturing

Company Profile

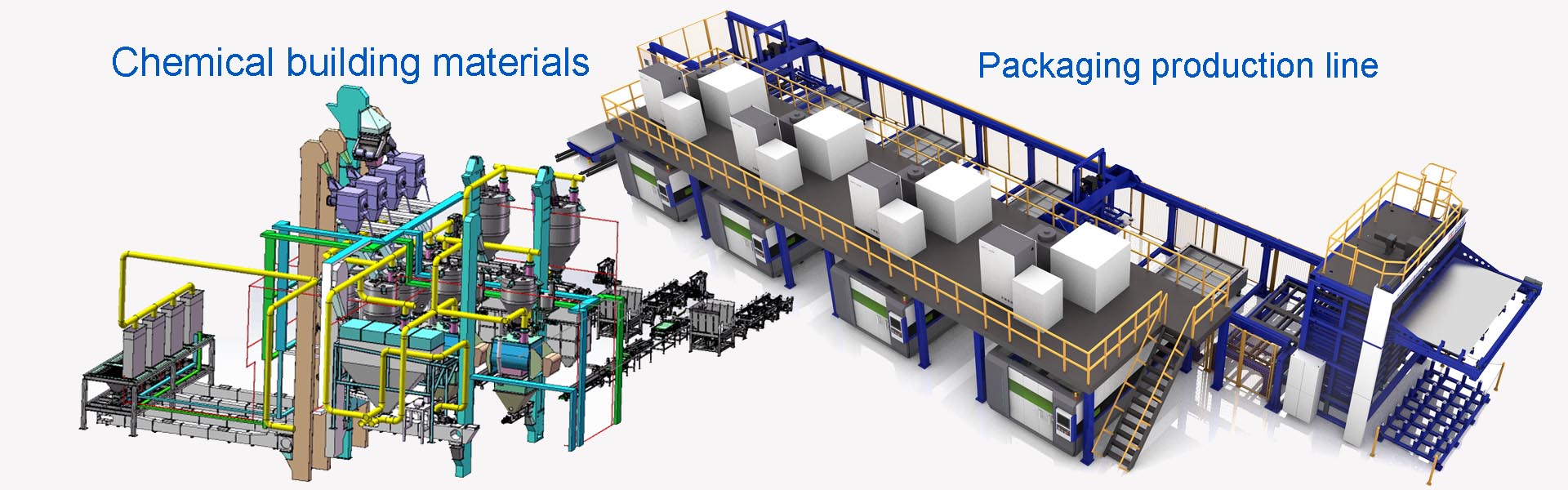

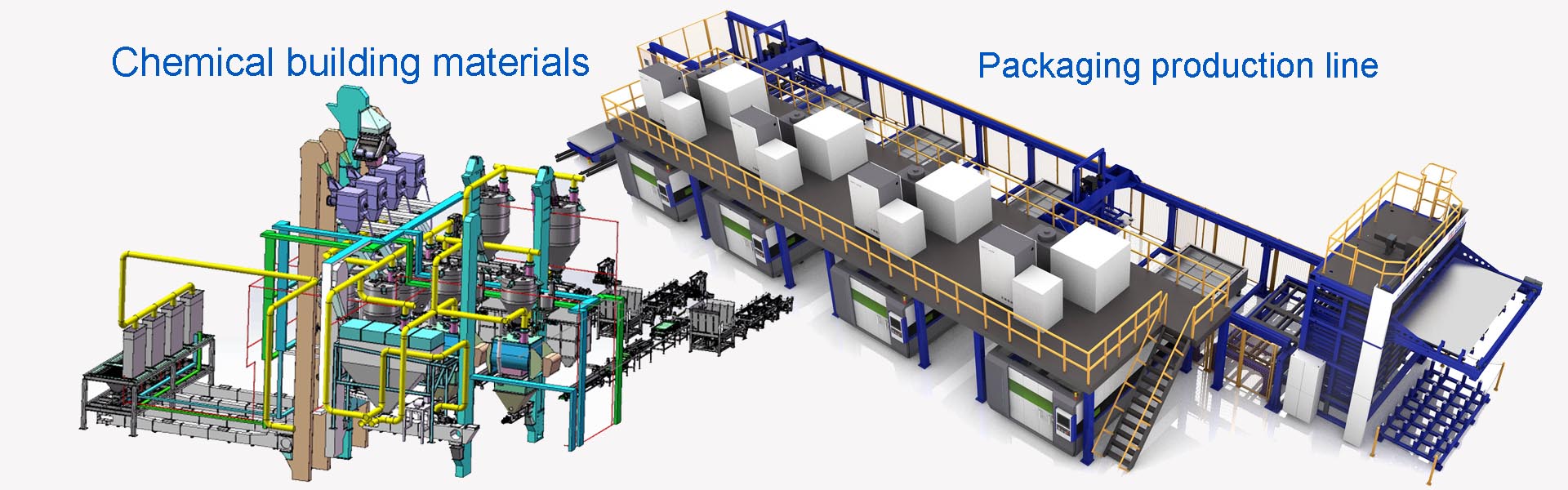

We specialize in manufacturing automatic filling and packaging systems, including:

Quantitative liquid fillers (paints, coatings, chemicals)

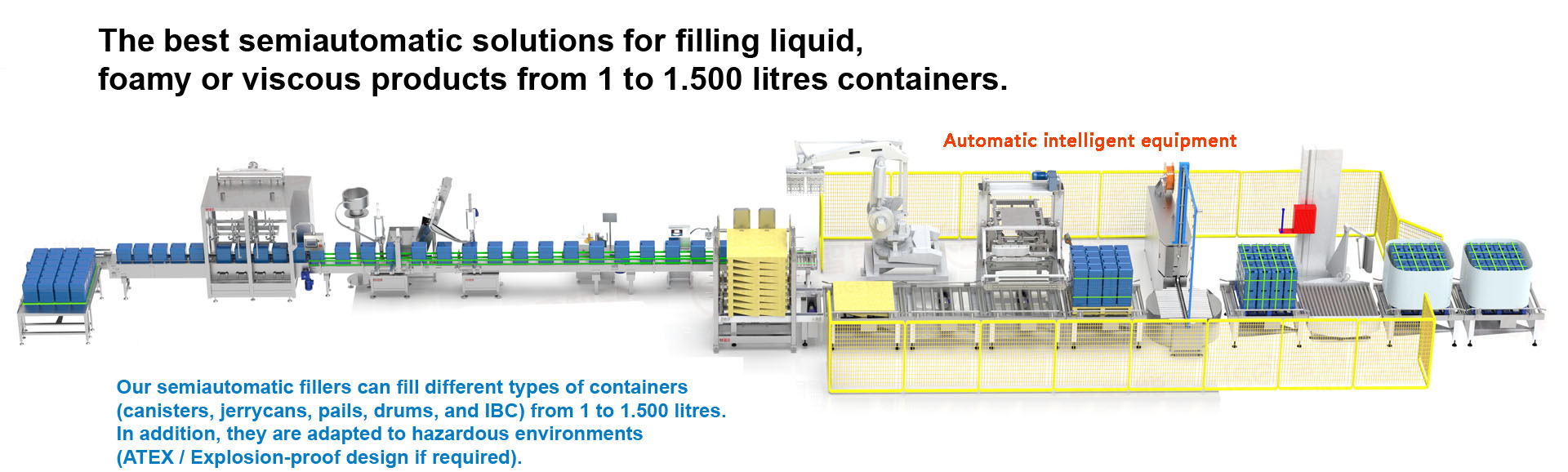

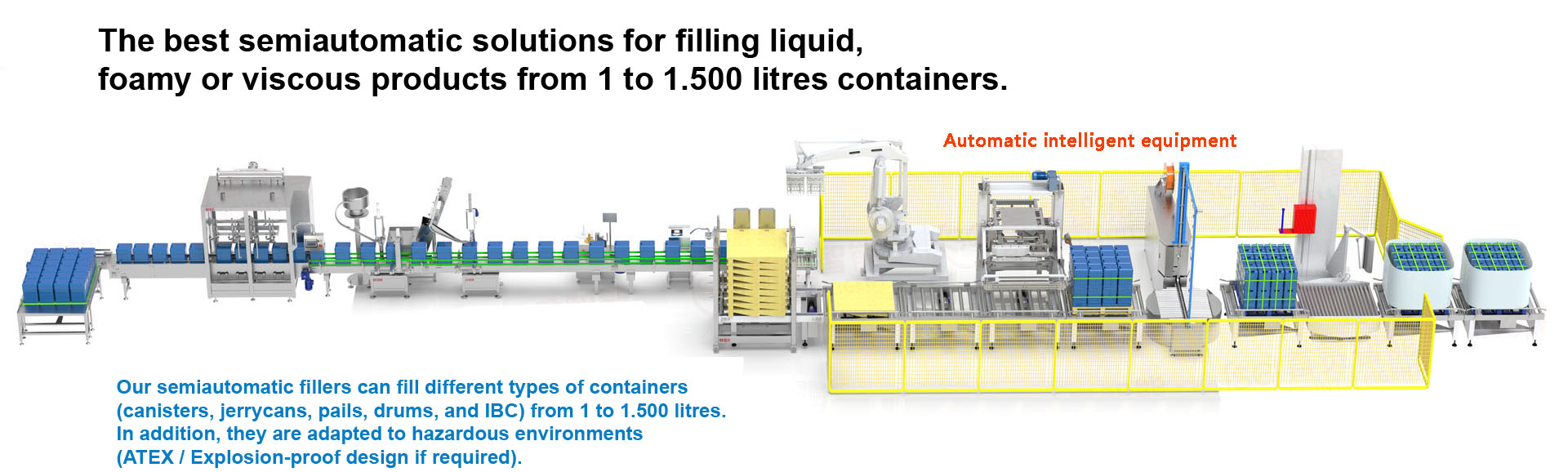

Semi-automatic/automatic capping, labeling, and palletizing lines

Explosion-proof 200L drum filling solutions

Product Overview: 200kg Automatic Quantitative Paint Filling Machine

A high-performance industrial solution for precise filling of paints, coatings, and solvents. Engineered with 316L stainless steel, explosion-proof design, and PLC automation, this machine ensures reliable operation in demanding manufacturing environments.

Technical Parameters

| Parameter | Details |

|---|---|

| Filling Range | 60–200kg per barrel (200L capacity) |

| Power Consumption | 0.5kW |

| Filling Speed | 30–60 barrels/hour |

| Voltage | AC220V±10% 50Hz |

| Filling Accuracy | ≤±0.2%FS |

| Air Consumption | 3–5m3/hour |

| Resolution | 50g |

| Air Pressure | 0.4–0.6MPa |

| Nozzles | 1 (adjustable height) |

| Dimensions | 3800(L)×1200(W)×1650(H) mm |

| Explosion-Proof Rating | ExdIIBT4 (ATEX/IECEx certified) |

| Barrel Compatibility | All 200L drum types |

Key Features

20-Product Preset Memory

Stores parameters for 20 formulations, simplifying changeovers.

Multi-Stage Filling

2-stage (fast/slow) or 3-stage (slow/fast/slow) modes for ±0.2% accuracy.

Drip-Proof Design

High-viscosity nozzle with anti-drip mechanism; low-viscosity model includes drip cup and vapor hood.

Crash Protection

Auto-retract function prevents nozzle damage from misaligned barrels.

Versatile Filling Modes

Submerged, surface, or top-fill options for diverse liquid properties.

Safety Interlocks

Nozzle engagement only when barrel is properly positioned.

Auto-Tare Correction

Compensates for container weight variations automatically.

Operational Workflow

Manual barrel placement → 2. Auto-convey to filling station → 3. Auto-alignment and nozzle insertion → 4. Two-stage filling (fast/slow) → 5. Auto-stop at target weight → 6. Manual capping and removal.

Applications

Liquids: Paints, coatings, resins, solvents, and lubricants.

Industries: Automotive, aerospace, construction, and furniture manufacturing.

Why Choose This Machine?

Explosion-Proof: ExdIIBT4 certification for hazardous areas.

Precision Engineering: 50g resolution with ±0.2% accuracy.

Chemical Resistance: 316L stainless steel and PTFE seals for corrosive materials.