Automatic drum filling equipment

Automatic drum filling equipment

- Brand::

- Model::

Automatic drum filling equipment

Automatic drum filling equipment

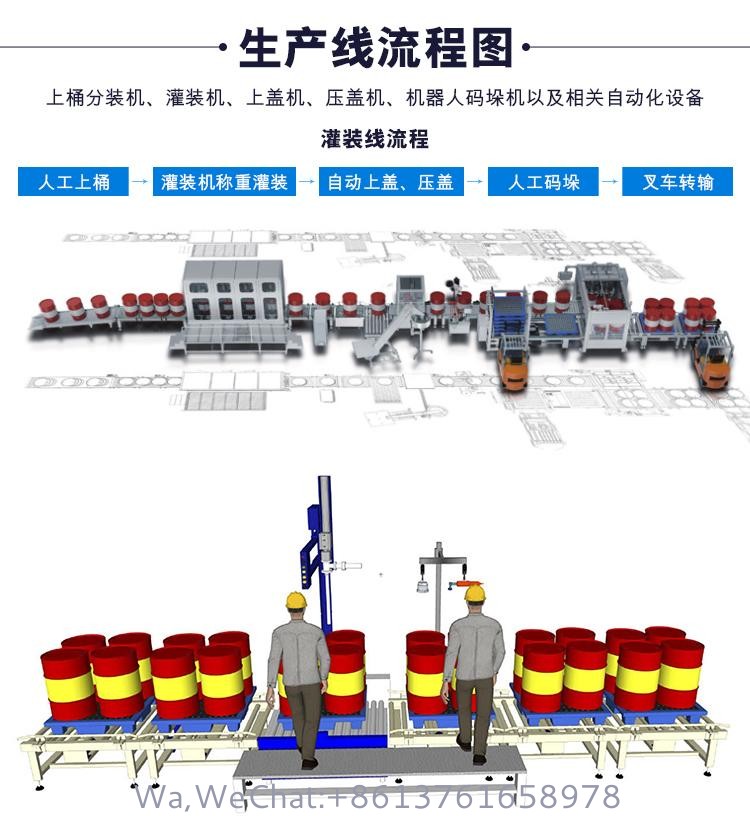

Automatic Drum Filling Equipment refers to advanced industrial systems designed to fill drums or containers with liquids, powders, granules, or other materials in a fully automated or semi-automated manner. These systems are widely used in industries such as chemicals, pharmaceuticals, food and beverage, cosmetics, and lubricants, where precision, efficiency, and safety are critical.

High Precision: Uses load cells, flow meters, or other measuring systems to ensure accurate filling.

Automation: Reduces manual labor and minimizes human error.

Versatility: Can handle various drum sizes (e.g., 5-gallon to 55-gallon drums) and types (open-top, tight-head).

Material Compatibility: Designed for liquids, pastes, powders, and granular materials.

Safety Features: Includes spill containment, overfill protection, and explosion-proof options for hazardous materials.

Customization: Can be tailored to specific product viscosities, drum sizes, and production requirements.

Ease of Operation: Equipped with user-friendly interfaces (PLC or HMI) for easy setup and monitoring.

Liquid Drum Fillers:

Designed for filling liquids such as chemicals, oils, solvents, and beverages.

Uses pumps (e.g., diaphragm, piston, or peristaltic) for precise liquid transfer.

May include features like foam control and drip-free nozzles.

Powder Drum Fillers:

Used for filling dry products like powders, granules, or flakes.

Employs augers or vacuum systems for accurate dispensing.

Includes dust collection systems to maintain a clean working environment.

Viscous Product Fillers:

Designed for thick or semi-solid materials like pastes, gels, or adhesives.

Uses positive displacement pumps or piston fillers.

Palletized Drum Fillers:

Fills multiple drums arranged on a pallet simultaneously.

Integrates with pallet handling systems for high-volume production.

Filling Nozzles: Designed to prevent spills and ensure clean filling.

Load Cells or Sensors: For accurate weight or volume measurement.

Conveyor System: Moves drums into and out of the filling station.

Pumping System: Transfers liquid or viscous products (e.g., diaphragm pumps, gear pumps).

Control Panel: PLC or HMI for easy operation and monitoring.

Dust Collection System: For powder filling applications.

Safety Features: Overfill protection, spill containment, and emergency stop.

Increased Efficiency: Faster filling speeds and reduced downtime.

Improved Accuracy: Consistent and precise filling reduces product waste.

Labor Savings: Reduces the need for manual labor.

Enhanced Safety: Minimizes operator exposure to hazardous materials.

Scalability: Suitable for both small-scale and high-volume production.

Compliance: Helps meet industry standards and regulations.

Chemical manufacturing (e.g., solvents, acids, adhesives)

Pharmaceutical production (e.g., syrups, powders)

Food and beverage industry (e.g., oils, sauces, beverages)

Cosmetics and personal care (e.g., lotions, creams)

Lubricants and oils (e.g., motor oil, grease)

Paints and coatings

Material Type: Ensure the machine is compatible with the product (liquid, powder, etc.).

Drum Size and Type: Check if the system can handle the required drum sizes and configurations.

Production Volume: Choose a machine that meets your throughput requirements.

Accuracy Requirements: Select a system with the appropriate level of precision.

Safety and Compliance: Look for features like explosion-proof construction if handling hazardous materials.

Integration: Consider how the machine will integrate with existing equipment (e.g., capping, labeling, palletizing).

Fillmore: Known for versatile drum filling systems.

Accutek: Offers a wide range of liquid and powder filling machines.

APACKS: Specializes in automated filling and packaging solutions.

Bulk Lift: Provides drum handling and filling equipment.

Liquid Packaging Solutions: Offers custom drum filling systems.

Automatic drum filling equipment is ideal for businesses looking to improve efficiency, accuracy, and safety in their filling processes. By automating the drum filling process, companies can reduce labor costs, minimize product waste, and increase overall productivity.