Paint filling machine

Paint filling machine

- Brand::

- Model::

Paint filling machine

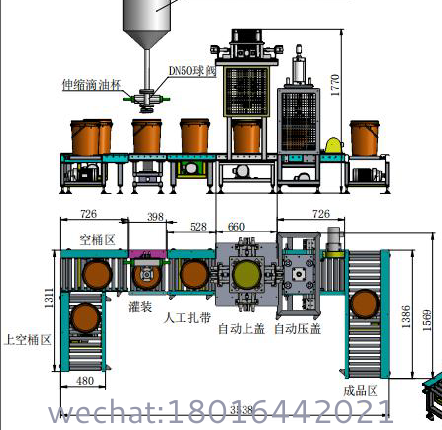

A paint filling machine is an industrial device designed to automate the process of filling paint into containers such as cans, buckets, or drums. These machines are widely used in the paint manufacturing industry to ensure accuracy, speed, and consistency in filling operations. They help reduce manual labor, minimize waste, and improve production efficiency.

High Precision:

Ensures accurate filling volumes to meet product specifications and reduce material waste.

Versatility:

Can handle various types of paint (e.g., water-based, oil-based, acrylic, enamel) and container sizes.

Automation:

Fully or semi-automated systems reduce human intervention and increase production speed.

Durability:

Made from materials resistant to corrosion and wear, as paints can be abrasive or corrosive.

Easy Cleaning and Maintenance:

Designed for quick cleaning and maintenance to avoid cross-contamination between different paint types.

Customizable:

Can be tailored to specific production needs, such as filling speed, container type, and paint viscosity.

Semi-Automatic Filling Machines:

Require some manual intervention, such as placing and removing containers.

Suitable for small to medium-scale production.

Fully automated systems that handle container placement, filling, and sealing.

Ideal for large-scale production.

Piston Filling Machines:

Use a piston mechanism to dispense paint accurately.

Suitable for thick or high-viscosity paints.

Gravity Filling Machines:

Rely on gravity to fill containers.

Best for low-viscosity paints.

Pump Filling Machines:

Use pumps to transfer paint into containers.

Ideal for medium to high-viscosity paints.

Rotary Filling Machines:

Designed for high-speed production lines.

Multiple filling heads allow simultaneous filling of several containers.

Paint manufacturing and packaging.

Filling of other liquid products like varnishes, coatings, and adhesives.

Industrial and commercial paint production.

Increased Efficiency: Faster filling speeds and reduced downtime.

Consistency: Uniform fill levels across all containers.

Cost Savings: Reduced material waste and labor costs.

Hygiene and Safety: Minimized human contact with hazardous materials.

Production Volume: Match the machine's capacity to your production needs.

Paint Viscosity: Ensure the machine can handle the thickness of your paint.

Container Type and Size: Verify compatibility with your packaging.

Budget: Balance cost with features and long-term benefits.

Ease of Cleaning: Important for switching between different paint types.

If you're looking for a specific type of paint filling machine or need assistance in selecting one, feel free to provide more details!