20L Carboy Can Liquid Filling Machine

20L carboy can liquid filling machine is a specialized piece of equipment designed to accurately and efficiently fill 20-liter carboys (large, rigid containers typically made of plastic or glass) with liquids. These machines are commonly used in industries such as chemicals, food and beverage, pharmaceuticals, and cosmetics, where large volumes of liquids need to be packaged in a hygienic and precise manner.

Key Features of a 20L Carboy Liquid Filling Machine

High Capacity: Designed to handle 20-liter carboys, making it ideal for bulk liquid filling.

Accuracy: Ensures precise filling volumes, minimizing product waste and ensuring consistency.

Versatility: Can handle a wide range of liquids, including water, oils, chemicals, syrups, and viscous products.

Durability: Constructed with materials resistant to corrosion and chemical damage (e.g., stainless steel).

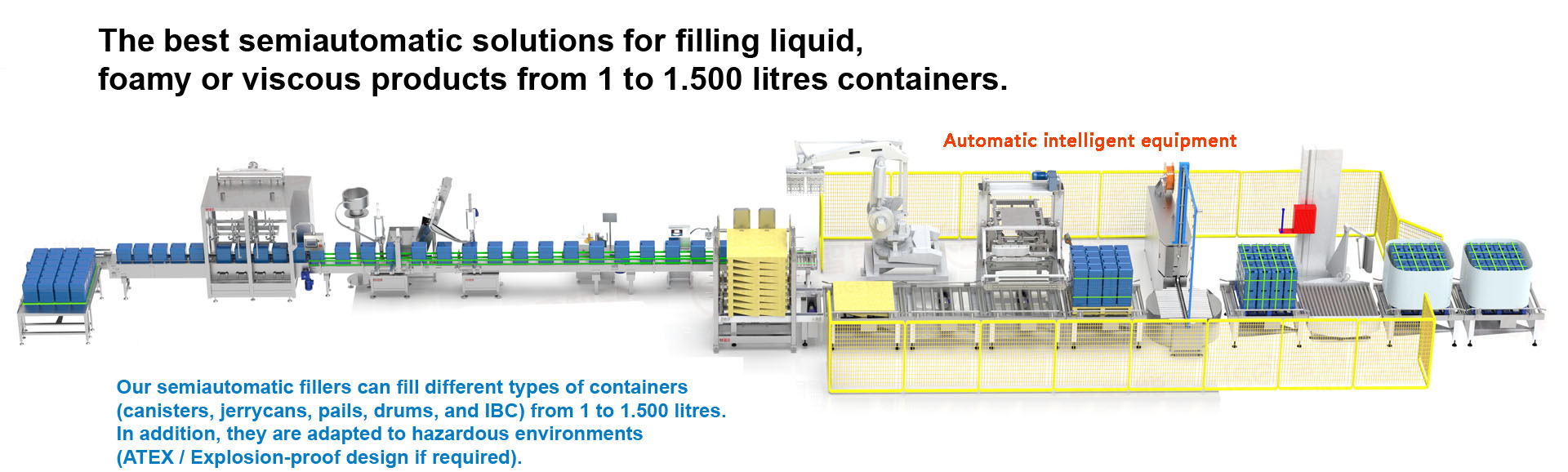

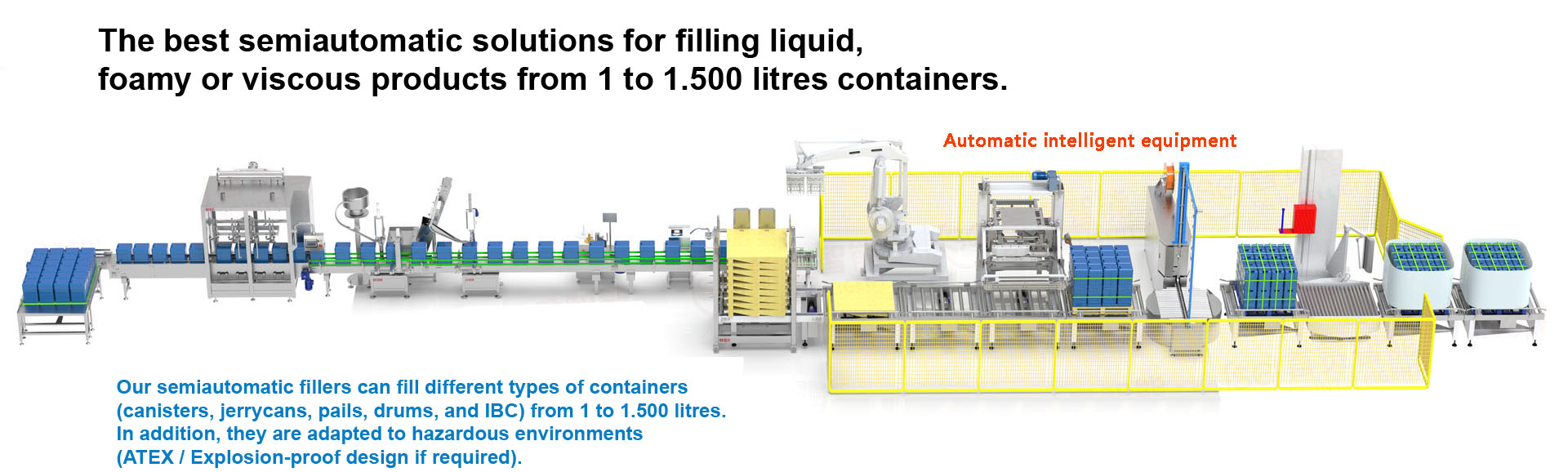

Automation Level: Available in semi-automatic and fully automatic models.

Safety Features: Includes overflow prevention, splash guards, and emergency stop functions.

Ease of Cleaning: Designed for easy disassembly and cleaning to maintain hygiene standards.

Types of 20L Carboy Liquid Filling Machines

Semi-Automatic Filling Machines:

Requires manual placement of carboys on the filling station.

Operator initiates the filling process (e.g., via foot pedal or start button).

Suitable for small to medium-scale operations.

Lower cost and simpler operation compared to fully automatic machines.

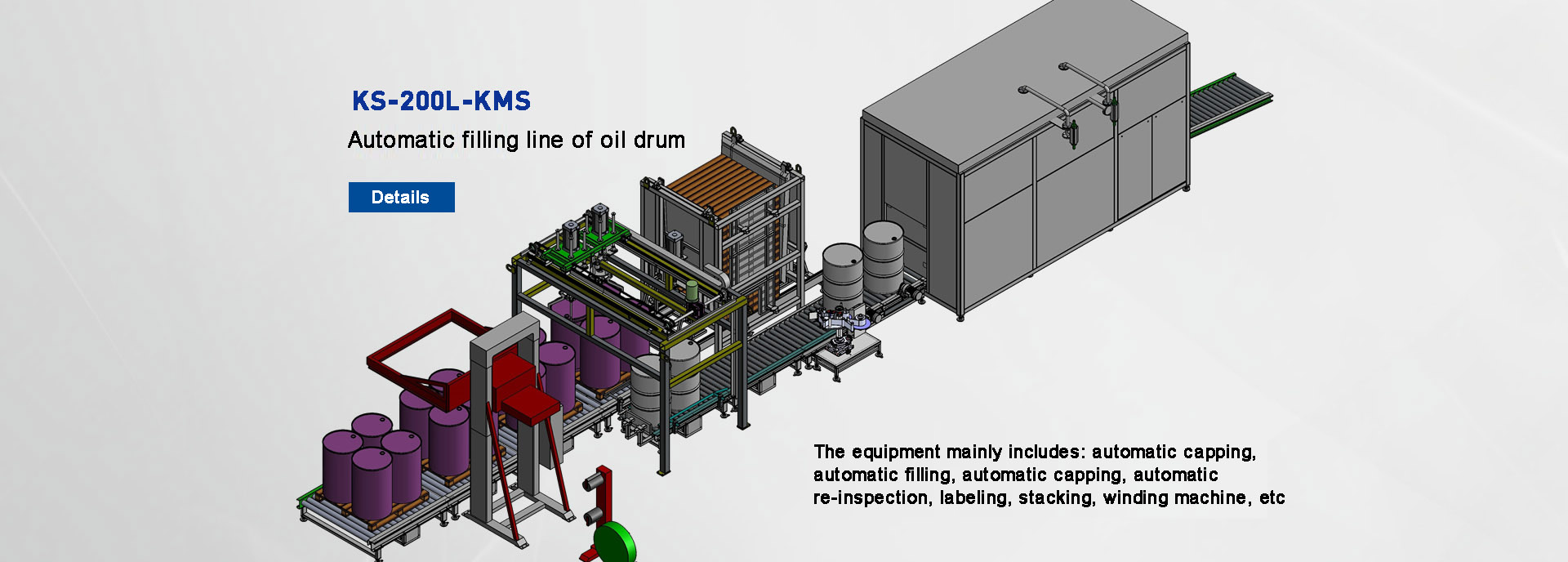

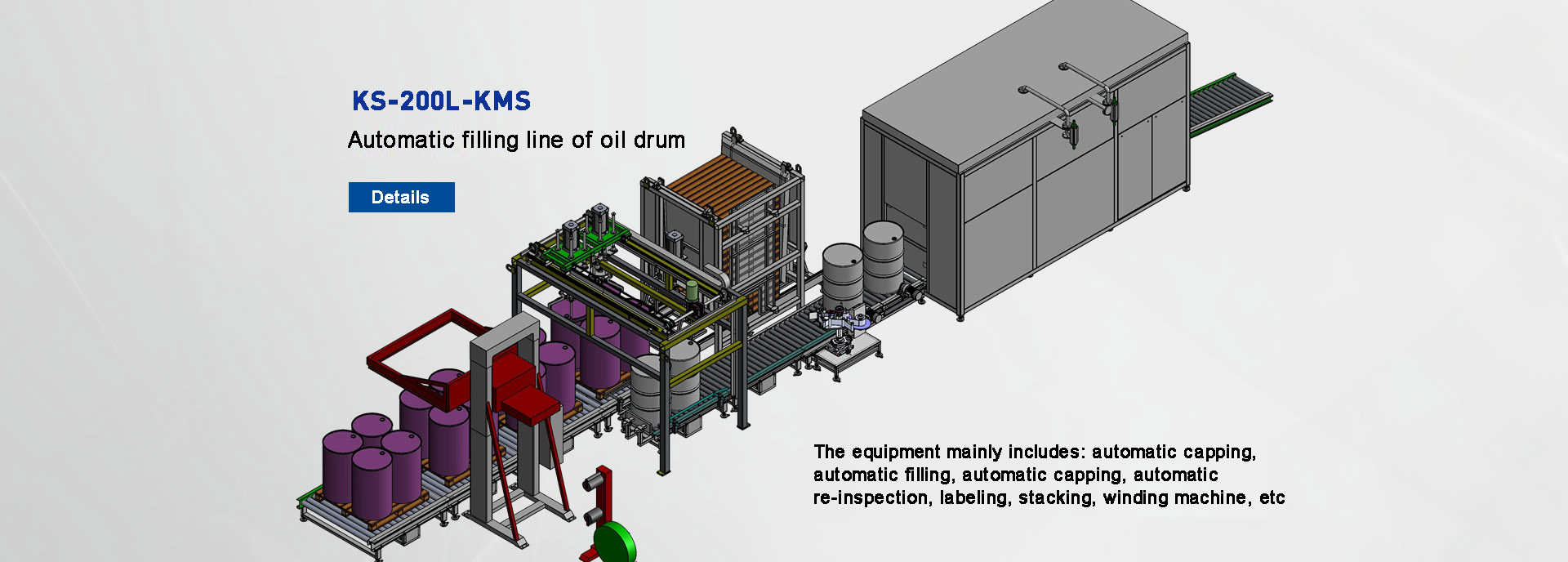

Fully Automatic Filling Machines:

Integrated with conveyor systems for automatic carboy handling.

No manual intervention required; the machine handles filling, capping, and sealing.

Ideal for high-volume production environments.

Higher initial investment but offers greater efficiency and throughput.

Components of a 20L Carboy Liquid Filling Machine

Filling Nozzle: Dispenses the liquid into the carboy. Can be designed for different liquid viscosities.

Pump System: Transfers liquid from the storage tank to the filling nozzle. Options include piston pumps, gear pumps, or peristaltic pumps.

Weighing System: Ensures accurate filling by weight (gravimetric filling) or volume (volumetric filling).

Conveyor System: Transports carboys to and from the filling station (common in fully automatic models).

Control Panel: Allows operators to set parameters such as fill volume, speed, and batch size.

Safety Features: Includes splash guards, emergency stop buttons, and overflow prevention mechanisms.

Applications

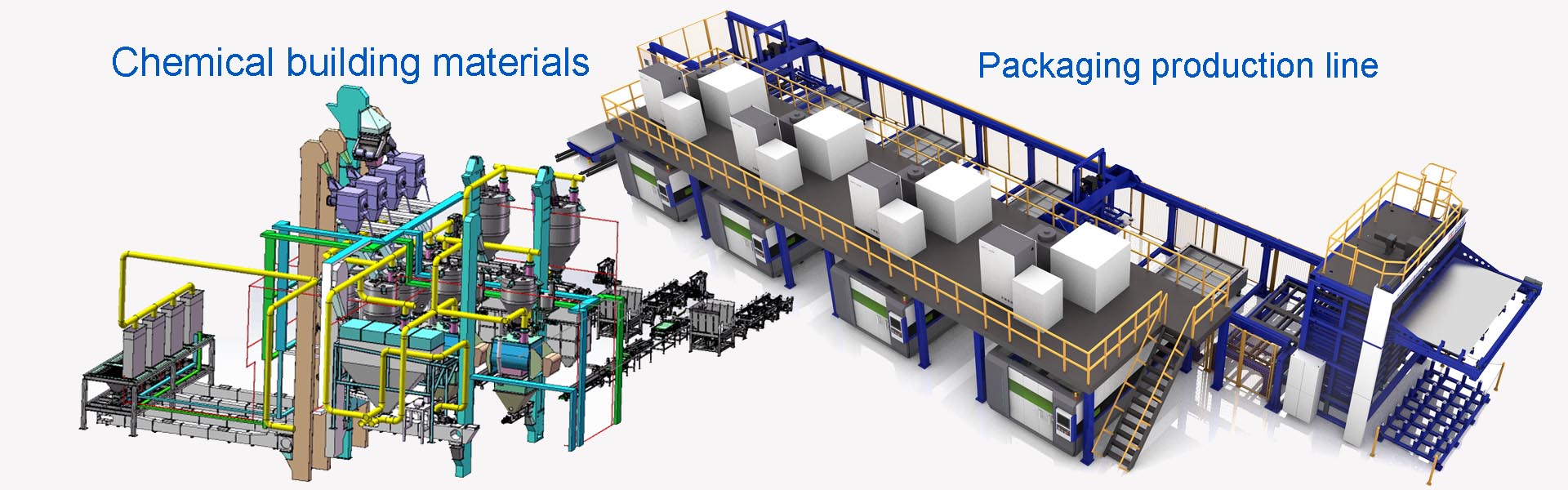

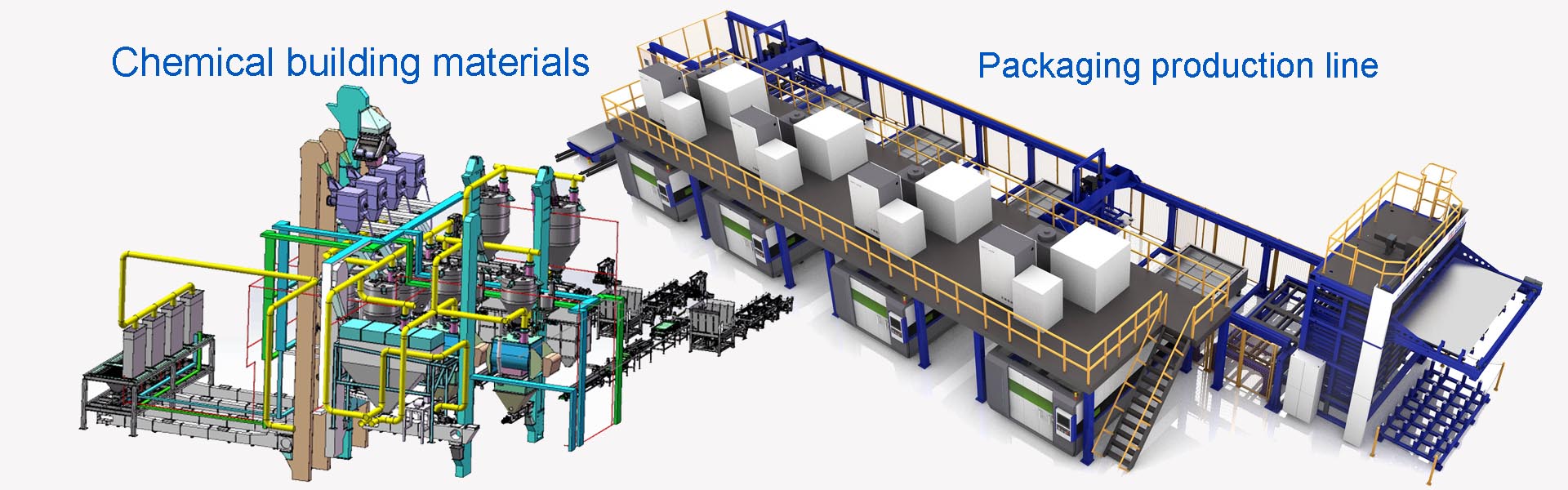

Chemical Industry: Filling solvents, acids, alkalis, and cleaning agents.

Food and Beverage Industry: Filling oils, syrups, juices, and sauces.

Pharmaceutical Industry: Filling liquid medications, sanitizers, and disinfectants.

Cosmetics Industry: Filling lotions, creams, and gels.

Water Treatment: Filling purified or distilled water.

Advantages

High Efficiency: Reduces filling time and increases production rates.

Precision: Ensures consistent fill levels, reducing product waste.

Hygiene: Minimizes contamination risks, especially in food and pharmaceutical applications.

Labor Savings: Reduces the need for manual labor, lowering operational costs.

Scalability: Can be integrated into larger production lines for fully automated operations.

Choosing the Right Machine

When selecting a 20L carboy liquid filling machine, consider the following factors:

Liquid Type: Ensure the machine is compatible with the viscosity and chemical properties of the liquid.

Production Volume: Choose between semi-automatic (lower volume) and fully automatic (high volume) models.

Accuracy Requirements: Determine whether gravimetric or volumetric filling is needed.

Budget: Semi-automatic machines are more affordable, while fully automatic machines offer higher efficiency at a higher cost.

Space and Integration: Consider the available space and whether the machine needs to integrate with other equipment (e.g., capping, labeling).

Popular Manufacturers and Suppliers

If you’re looking to purchase or customize a 20L carboy liquid filling machine, it’s important to consult with a reputable supplier to ensure the equipment meets your specific needs. Many manufacturers offer tailored solutions based on your production requirements and product characteristics.